|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Three-in-one solution |

| Home> | Handbooks | >Manufacturing Matters Ireland | >Three-in-one solution |

Three-in-one solution

10 December 2013

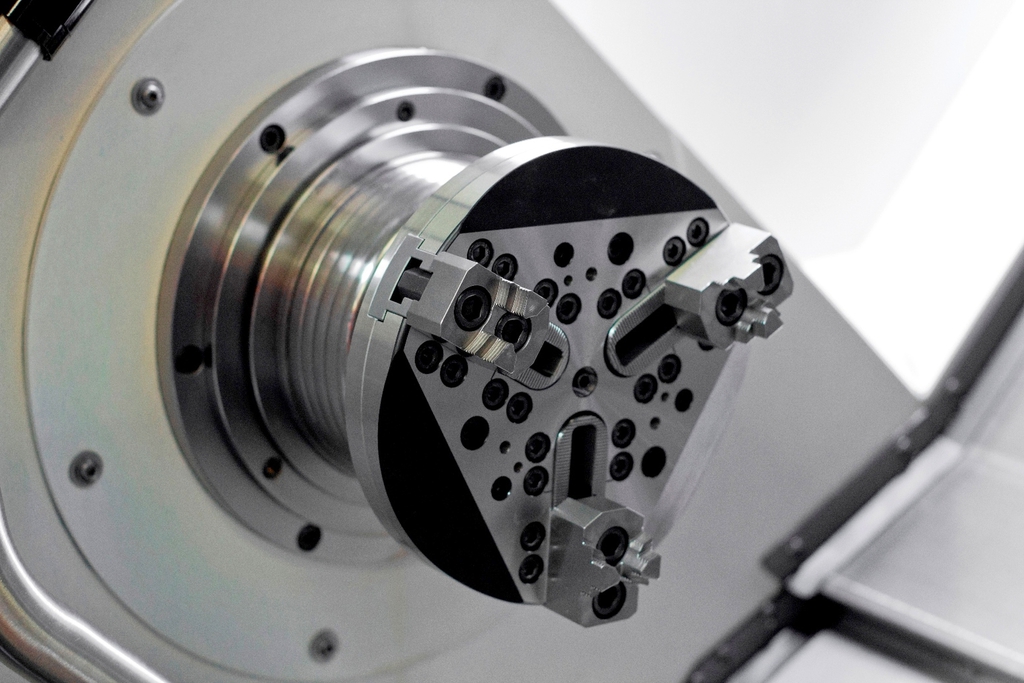

Available from Leader Chuck Systems, a new compact modular system from Hainbuch is said to redefine jaw clamping and mark the beginning of a new era in workholding.

The Jaw Module is flexible, can be quickly changed, and covers a large clamping range. Available in two sizes, the 144 clamps from 25 to 115mm, and the 215 clamps from 25 to 200mm diameter. The system is suitable for sensitive clamping and delicate components, can be used as a pick-up chuck on sub-spindles, and is suited to stationary prismatic applications.

Together with the Hainbuch Spanntop chuck, Jaw Module forms a quick-change clamping solution. Mandrels and clamping heads can also be used in the basic unit, with quick and repeatable set-up. The new module completes the circle and provides a new clamping dimension that opens up even more possibilities for users.

Mark Jones, MD, says: "We’ve been working with Hainbuch for 20 years now and these 2014 modular solutions make sense as they are as capable of multitasking as many of today's machine tools. Using the new small Jaw Module, about 80% of usual components are covered; for larger components it can be easily changed to a large Jaw Module within 30 seconds.”