|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Work table solutions |

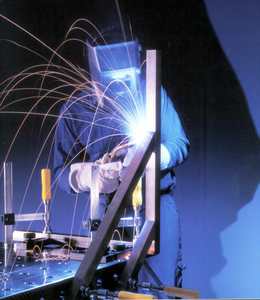

Work table solutions

24 January 2014

Now available from Surface Technology Products (Surtech) is the extended range of welding, jigging and fixturing tables from Siegmund Group.

Incorporating a 3D modular positioning and clamping system for fast, precise and economical production, work tables are manufactured to a tolerance of 0.03mm.

They offer a high degree of flexibility, and bespoke solutions can be created to meet the demands of individual users and applications.

The tables are manufactured from high quality plasma nitrided steel with a hardness of over 700 Vickers to deliver scratch and erosion resistance as well as protection against impact and welding spatter adhesion.

Applications include robotic and manual welding stations, jigging, fixturing, measuring, monitoring and assembly stations as well as bending and folding stations.

Some of the largest welding projects can be found in the construction, bridge building, ship building, nuclear energy plants, wind energy assemblies and oil drilling platforms. Simple flat or three dimensional welds are well suited for Siegmund’s modular welding tables where individual open frame tables can be installed to deal with virtually any size and any weight, with single tables supporting up to 5000kg and two tables joined together up to 10,000kg with a dimensions up to 2700 x 11500mm.

In the robotics industry, rotary turntables can be integrated with modular welding tables to robotically weld sheet metal fabrications. Such units can be configured to allow an operator to load and unload at one station whilst the robot welds on the work station. To further improve versatility, positioning systems can be added.

In the automotive industry the tables have proven a resounding success among manufacturers of racing cars, HGVs, fire engines, go carts and golf carts. This industry benefits from the flexibility and accuracy when new dedicated welding jigs can be designed and built within hours rather than weeks.

With regard to industries that require small welding procedures, the benches have delivered good results. In the case of tool boxes, enclosures and many other small items that are perfectly square, it is essential they are welded accurately and consistently to function properly. In such instances, the Siegmund modular welding tables with high precision grids and a vast range of clamping tools are said to guarantee repeatability with accuracy.

In the sheet metal industry, set ups for welding take a lot of time and require highly skilled operators. The Siegmund method can save time when setting up and is said to reduce welding time by cutting down on heat distortion. In this sector, a key benefit is that Siegmund tables are made from low carbon, high tensile steel to minimise carbon migration when stainless steel is used.