|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Thermography | >Spots cockpit faults |

Spots cockpit faults

16 June 2014

A Dutch company specialising in electrical inspection recently won a contract from the Danish cargo airline, Star Air, on the strength of its thermal imaging camera’s ability to see thermal anomalies in great detail.

Aircraft cockpit inspections comprise a wide range of routines. Whilst this work is vital, aircraft time on the ground is costly. Star Air was therefore very interested in a solution proposed by Thermografisch & Adviesbureau Uden to use thermal imaging as a way of speeding up electrical inspection without any compromise on accuracy and reliability.

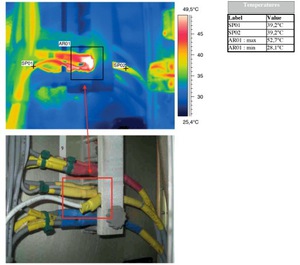

The trial inspection on the cockpit of a Boeing 767-200 freight aircraft was a success. The inspection team used a FLIR P640 thermal imaging camera and it immediately provided evidence of a defect in a resistor.

"Thermal imaging has proved great for cockpit inspection, because it gives us an instant and accurate view of the condition of our aircraft systems,” commented Carsten Holm, technical vice president, Star Air. "We do everything in our power to guarantee that all equipment is operating optimally and safely. FLIR thermal imaging is helping us to achieve that.”

- Cameras on show

- Thermal imaging: Automatic level and span adjustment

- Thermal sensitivity gets a boost

- Spot thermal imaging camera - see heat and measure it

- High resolution

- Low on price

- Tough approach to latest camera

- Worldwide MSX demand fuels cost reduction

- Thermal camera for automation applications

- Latest cameras: One touch automatic level and span adjustment