|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Hand and power tools | >Thread fixing tools |

| Home> | Efficient Maintenance | >Maintenance products | >Thread fixing tools |

Thread fixing tools

23 September 2014

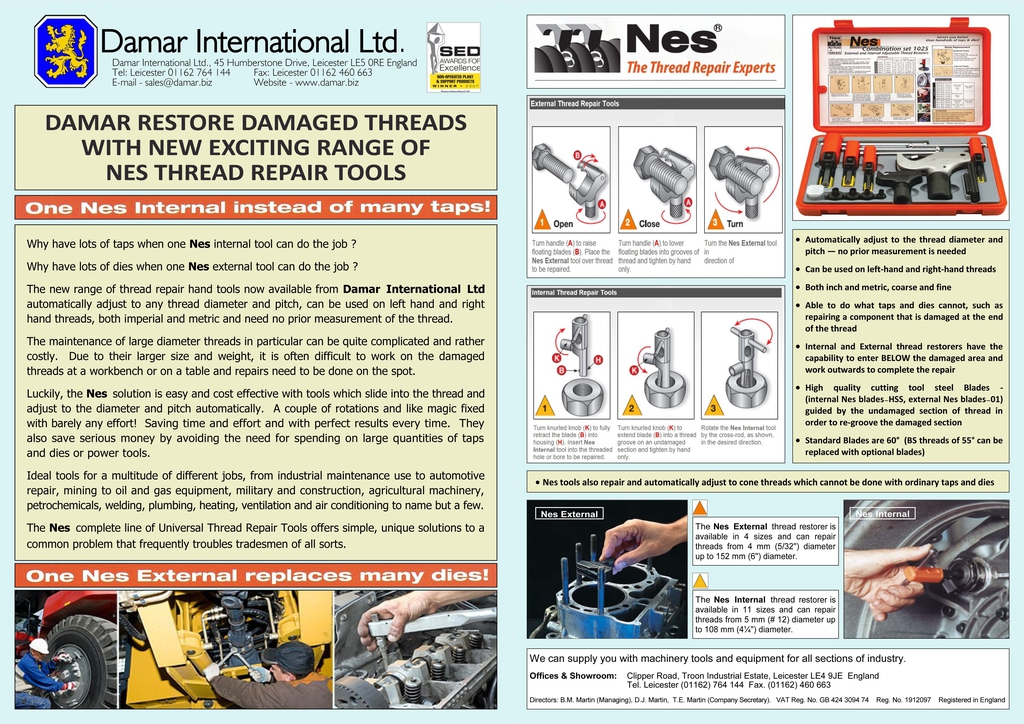

In a UK agreement with NES, Damar International is selling the NES Thread Repair Tool. The internal tool and external tool eliminate the need for stocking taps and dies in the hope that one will fit a maintenance issue arising from damaged threads.

Brian Martin, MD of Damar, explained: "Minimising expensive maintenance downtime is essential for all plant and equipment users in all types of industry. There is nothing more annoying and productivity zapping than a damaged threaded fastener. The NES internal and external tools make short work of fixing these problems to keep productivity high at all times. They are a small investment that easily pay for themselves many times over.”

The new range of thread repair hand tools automatically adjust to any thread diameter and pitch, can be used on left hand and right hand threads, both imperial and metric, and need no prior measurement of the thread.

The NES tool can be used, for example, in the maintenance of large diameter threads which is often challenging and costly. Large size and weight make it difficult to work on the damaged threads at a workbench so repairs need to be done on the spot. The NES thread repair tool deals with this problem easily, quickly and cost effectively. The NES slides into the thread and adjusts to the diameter and pitch automatically. A couple of rotations and the thread is fixed with barely any effort.

Damar says the NES tools can also repair threads where ordinary taps and dies would fail. These include cone threads, components that are damaged at the end of the thread and the tool can enter below a damaged area and work outwards to complete a repair.