|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Automation | >Speedy spot welding robot |

| Home> | Production Engineering | >Welding | >Speedy spot welding robot |

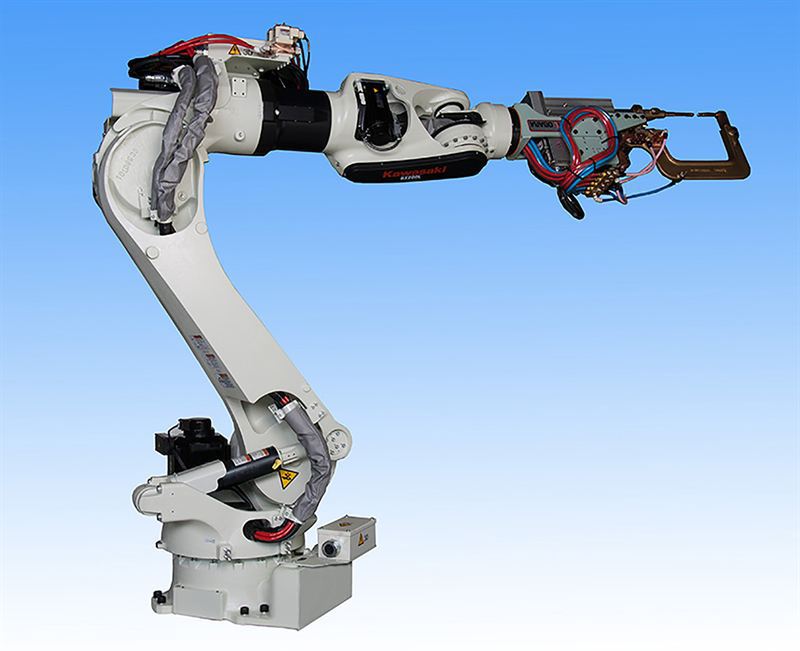

Speedy spot welding robot

22 August 2014

Kawasaki Robotics has introduced its latest spot welding robot range designed to meet market demand for faster welding speeds.

The B-Series has a small footprint of 0.5m wide and is suitable for densely populated robot cells, or stand-alone cells, where minimal space is available.

A slim, lightweight arm design and high-output motors, together with anti-vibration control technology, have helped reduce the time needed for short-pitch movements. Two payload variants,100 and 200kg, provide repeatability of ±0.2mm and linear speeds of 5m/s making the range suitable for high-volume spot welding requirements.

The cable has been integrated into the robot, preventing process snagging and eliminating cable positioning variables.

Using the latest Kawasaki E42 the B-Series robot has highly accurate trajectory control and faster programming execution. Supporting the robot's small footprint the E42 controller also offers a compact design. Additional axes control is available for applications requiring synchronised manipulation during the weld process.

- Multi-million cycle robot replaced after almost 20 years

- Robotic welding system

- Robots for moulding & post-moulding processes

- Smooth operator

- £750K investment pulls chair base production back to the UK

- Glass expert sees clear advantages with Kawasaki robots

- Robot swap aids production

- Supplier award

- Celebrating 20 years in the UK with 700kg addition to palletiser range.

- Robot at MACH