|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Synchronous drum motor |

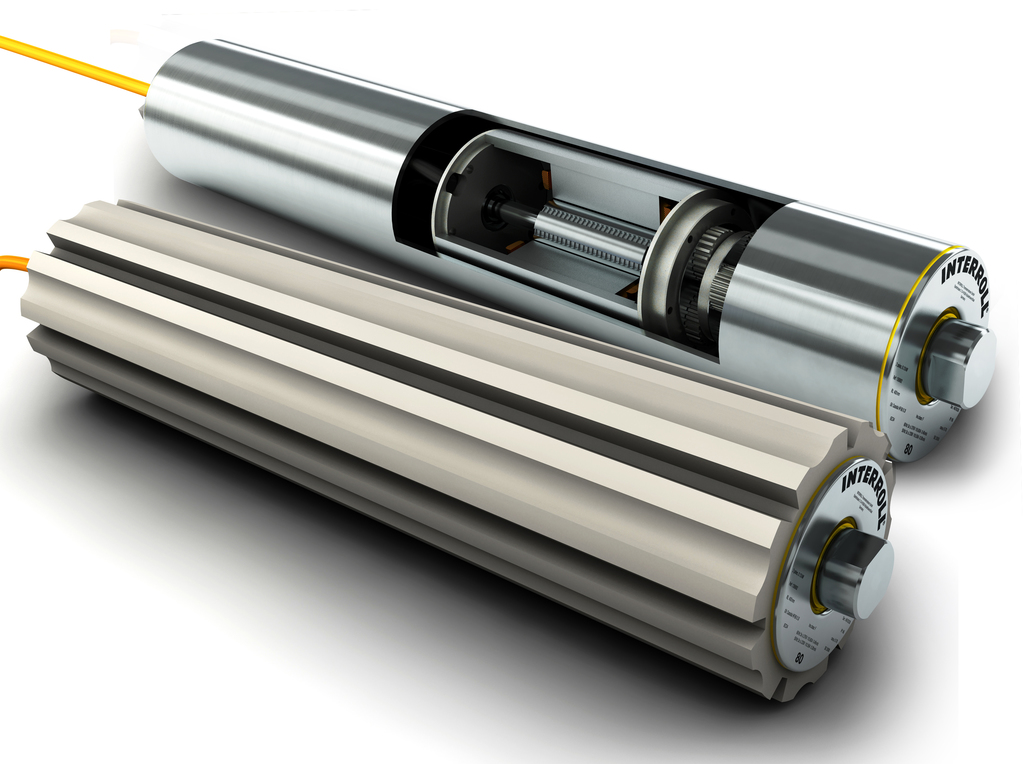

Synchronous drum motor

03 September 2014

Interroll will be exhibiting integrated drive solutions, including its new high torque synchronous drum motor, at PPMA 2014 (30th September to 2nd October, NEC).

The most powerful and eco-friendly energy efficient hygienic conveyor belt drive ever developed by Interroll provides a one drive system to suit all needs and speeds (0.01 to 4.5m/s). Its capabilities now expand into applications previously reserved for servo-drive technology.

Combined with an integrated encoder or other feedback system, the synchronous drum motor can accelerate from 0 to 100% of the maximum speed in milliseconds. It can be precisely controlled at both extremely high and ultra low speeds with fast and timely exact positioning.

Also on display will be the 24VDC Interroll RollerDrive EC310, which is said to use up to 30% less energy and recycles brake energy.

For modular plastic belt conveyors Interroll utilises a range of FDA approved profiled rubber and PU lagging, stainless steel or polymeric sprockets.

- Interroll launches new sorting system

- Wheely versatile

- Dynamic storage solutions

- Interroll intensifies exchange of expertise with digital channels

- Smart drive solutions and flexible conveyor modules

- Products for use in refrigeration applications

- On show in Dublin

- Modular drum motors

- Interroll announces new CEO

- Energy-efficient drives