|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Raising the profile |

Raising the profile

20 August 2014

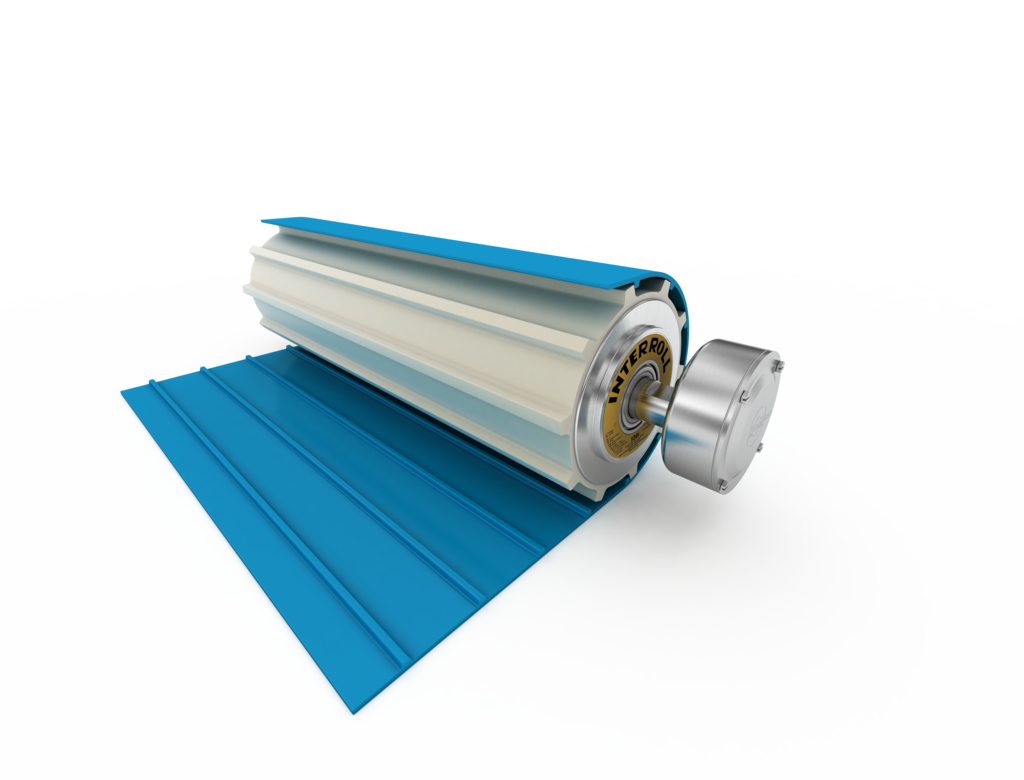

Interroll has developed the Interroll Multiprofile, a profile for its asynchronous drum motors and synchronous drum motors that feature frequency converters, which can be used to drive various conveyor belts from different manufacturers using only one Interroll Premium Hygienic PU Profile.

Customers can replace belts without having to replace the drum motor, reducing the time needed to retrofit and perform maintenance work on the conveyors. Furthermore, Interroll’s Multiprofile is said to contribute to lower storage and thus saves customers money and storage space.

The Multiprofile is made using the 'Interroll Premium Hygienic PU' which is a new development. This hygiene-friendly material complements the Interroll product line that meets EHEDG guidelines. The new material for rubber coating drum motors is well suited for positively driven belts and is known for its smooth surface that prevents bacteria from forming on the material. Besides its low noise level and high resistance to oil, grease and chemicals, the Premium Hygienic PU is reported to have much lower friction.

- Smart pallet mover introduced by Interroll

- Roller conveyor keeps cycling gear on track

- Survey prompts new pallet mover

- Interroll introduces new vertical crossbelt sorter

- Hygienic & energy efficient

- Interroll's lean, clean, conveying machine

- Synchronous drum motor boosts salmon slicing

- Smart drive solutions and flexible conveyor modules

- Efficiency improvements

- Modular conveyor platform