|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Contact-free temperature monitoring |

Contact-free temperature monitoring

30 September 2014

Visitors to the glasstec exhibition in Düsseldorf will find temperature monitoring solutions for virtually all stages of glass production and processing at the Raytek/Ircon stand.

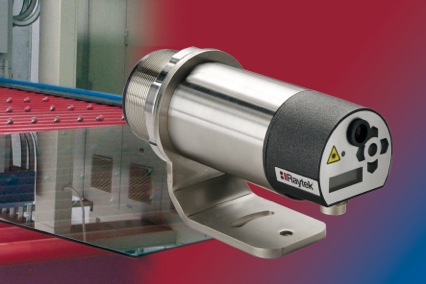

The experts in infrared temperature measurement offer a complete program of pyrometers and IR measuring systems for all temperature ranges. The contact-free systems ensure maximum reliability and speed without the risk of contaminating the product. Combined with high-performance software, they support automatic process control and complete quality documentation.

Raytek and Ircon share a booth with sister company Datapaq, a provider of data logger systems for in-process temperature profiling. A central exhibit is a combined Raytek and Datapaq solution for glass tempering: The Raytek GS150 infrared temperature monitoring system creates thermal images of all glass panels before entering the quench chamber, while the Datapaq Furnace Tracker system is used for process configuration and control, recording the temperature curve during preheating, in the furnace, and during quenching.

Ircon presents the versatile applications of its Modline 7 series. With suitable cooling equipment, these robust point sensors can be used at ambient temperatures to 315°C. The Modline 77 and 78 models for the production of float glass and ultra-thin drawn glass are among the exhibition highlights.

- Thermal imaging and furnace surveys

- Monitoring system for rotary kilns

- Non-contact temperature monitoring

- Heat protection range for temperature profiling in paint operations

- Noncontact temperature measurement

- New additions to spot pyrometer series

- Sensors now with Ex i certification

- Water cooled temperature sensors

- Single brand

- High-temperature pyrometers fit for harsh environs