|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cooling equipment | >Chiller hire aids machinery trial |

| Home> | Premises management/maintenance | >Hire equipment | >Chiller hire aids machinery trial |

Chiller hire aids machinery trial

27 January 2015

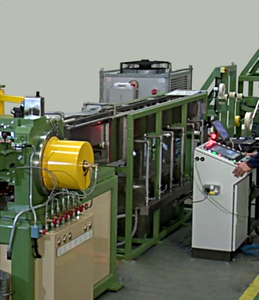

When a specialist machine builder needed to test-run bespoke built machinery that required a supply of chilled water both to cool manufactured components and to keep the machining heads at a constant temperature, a solution was provided by Andrews Chiller Hire

On a continuous, automatic rotary extrusion machine developed by the specialist machine builder there is a cooling trough positioned immediately after the actual extrusion processing head to quench the finished components. After pre-preparation non-ferrous feed stock enters the extrusion chamber entrance and is carried to an abutment, the forced forward motion creating friction and subsequent heat.

The increase in metal temperature creates a plastic state ready for forcing through a pattern die. The extruded tube or profile ejected from the die can be at temperatures in excess of 500°C.

The long quench trough provides staged cooling to achieve correct metallurgical properties of the finished non-ferrous products such as copper and aluminium conductors, copper bus bars, lightning and earthing strips, etc. then need to be cooled.

All sectors of the cooling trough have recirculating water pipes connected directly to an Andrews 50kW chiller where heated water is continuously drawn out to the chiller, circulates through its chilling process, chilled water continuous entering the trough to lower temperature. This cyclic process has to take into account that in the first cooling section there is a more significant rise on water temperature due to the extremely high component temperature.

The cooling application on the extrusion machine is one of the many industrial applications for which Andrews Chillers Hire equipment is used. Due to the nature and diversity of build program the machine builder hires as and when required and for only short periods to enable machine trials before despatch to their customers. "Hire is the most practical and most economical solution for our needs,” said a spokesperson for the company.

This versatile 50kW fluid chiller is part of the Andrews Sykes Chiller Hire range of temperature control equipment and ancillaries to satisfy all industrial cooling requirements providing cooling water to production processes or to bypass/assist permanently installed chillers. Within the confines of the compact frame of the 50kW model it encompasses heat exchanger, condenser, control system, compressor and circulating pumps. It comes mounted on a robust base plate, complete with lifting facility for easy on-site positioning.

Andrews Sykes Chiller Hire can supply air-cooled fluid air chillers with capacities from 6 to more than 750kW and operates out of an extensive nationwide network of depots.

- Be prepared should failure strike

- Planned chiller hire helps preserve stored food

- Counting the cost of ad hoc pump hire?

- Temperatures restored

- Pre-planned chiller hire helps preserve stored food

- Contingency chiller cover

- Compact low temperature heat pump chiller

- Preventing lost production

- Chiller hire keeps news on track

- Temporary chilled store

- Liquid cooling package

- Welder generators

- Next day delivery

- Bronze bestowed

- HAE apprentices trained to 'Hire Standard'

- New HR15 4x4 Shortlistes fopr the 'Product of the Year' award at the HAE Hire Awards of Excellence

- Boilers take the high road

- Efficiency boosted by hired help

- Awards winner

- Crawlers added