|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Training | >Ten steps to asset tracking |

ARTICLE

Ten steps to asset tracking

16 April 2015

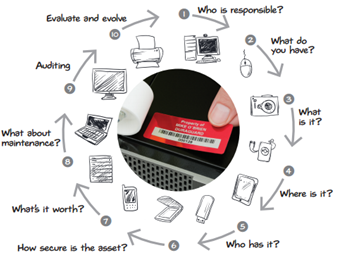

Seton suggests 10 simple steps to help companies track their assets.

- Who is responsible? Assign an asset manager to control, build and maintain your process. Formalise the asset management policy and communicate it to all employees

- What do you have? Create a comprehensive inventory. Consider the recording method – from simple written recording to sophisticated cloud-based software such as AssetGuard PRO.

- What is it? Ensure the asset manager has sufficient information about each asset for easy management / auditing.

- Where is it? Define whether the asset is mobile or fixed, and whether it is linked to a particular department /cost centre.

- Who has it? Provide information on the asset holder and details of any usage agreements between your organisation and the employee.

- How secure is the Asset? Use an appropriate Asset Tag / Label – you can include a barcode AND an asset number, and even a high durability or tamper evident Asset Tag.

- What’s it worth? Accurately value your inventory. Keep receipts.

- Maintain assets to ensure continued efficient functionality – consider organisational standards of maintenance and legal requirements e.g. PAT testing.

- Regularly assess the performance and usage of assets, repair costs and who is using them most effectively.

- Evaluate and evolve: Review your Asset Management Policy regularly – it is a dynamic and will change as your business changes. www.seton.co.uk/asset_tags

MORE FROM THIS COMPANY

- In-house signs

- Safety identification: Easy design

- ISO 20560: a global standard to identify pipe contents

- Save time with cable identification. Download the Guide.

- Powerful precision - simply intuitive: New M410 and M510 Label Printers from Brady

- Lockout/tagout solutions

- Temperature indicating labels

- RFID or barcode? Make the right decision for your asset tracking

- Easily automate product identification and improve traceability

- Easy safety identification

RELATED ARTICLES

- Training tailored to brewery needs

- Asset Management: Standard Practice

- Help with problem solving

- Inspection, test & monitoring: A choice of career development pathways

- Savings in store

- Guide to live electrical system inspections

- Revised guidance on asbestos

- Learn more about thermography

- Hose integrity, inspection and management

- Improve your skills and knowledge on rolling bearings and condition monitoring

OTHER ARTICLES IN THIS SECTION