|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Non-contact monitoring |

Non-contact monitoring

15 October 2015

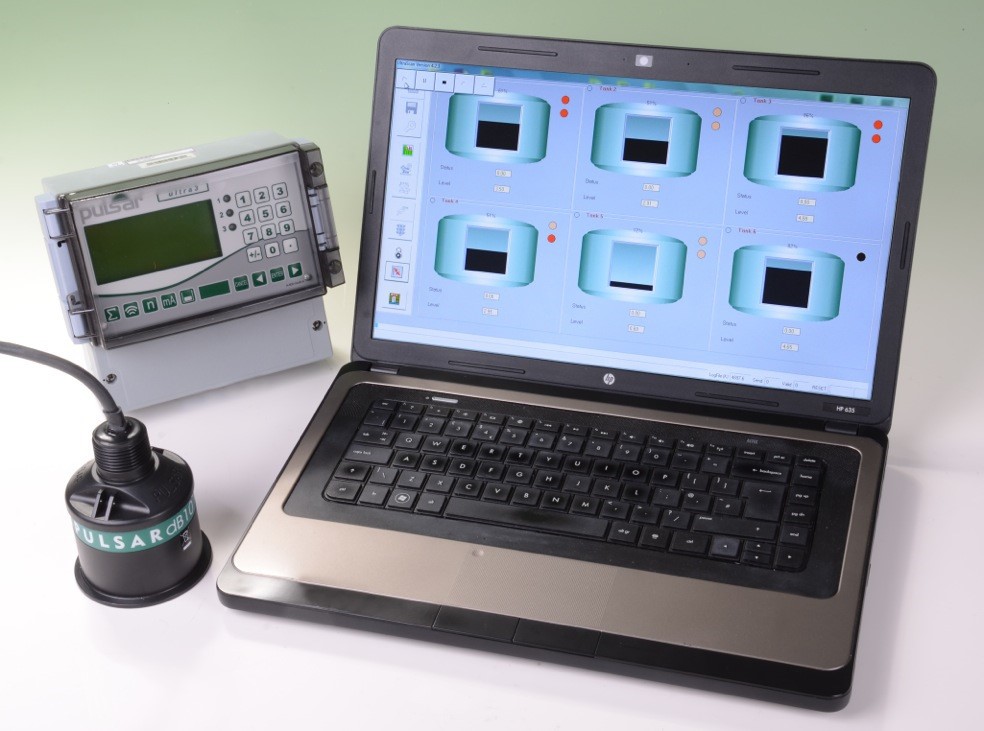

Pulsar Process Measurement has supplied non-contacting ultrasonic volume measurement equipment and associated remote plant mimic software to Northern Rail, allowing the more efficient control, delivery and use of fuel.

Contractor Austin-Lenika identified that the existing level indicators were not suitable for the application and approached Pulsar for a solution. They specified that new equipment should provide a measurement of the volume of fuel in the bulk tanks with a target of ±1% accuracy.

Pulsar supplied Ultra 3 non-contacting ultrasonic level measurement controllers with associated dB series transducers. The transducers were mounted into flanges at the top of the fuel tanks, and operate on a ‘time of flight’ principle, an ultrasonic signal reflecting back to the transducer from the surface of the fuel.