|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Weighing equipment | >Ultrasonic success |

Ultrasonic success

03 August 2016

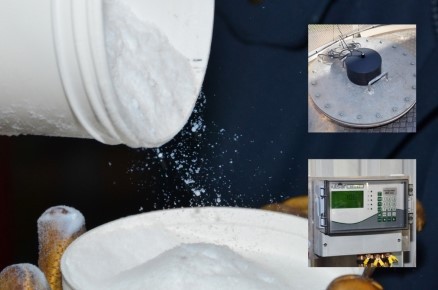

Bulk measurement of finished Fumed Silica can be extremely difficult which is why Cabot Carbon turned to Pulsar’s non-contacting ultrasonic technology when trying to measure the contents of their silo after other approaches had failed.

All non-contacting measurement methods rely on being able to bounce a signal back from a material surface and measure the time taken for it to reach a transducer. The challenge is to supply a signal with enough energy, then discriminate that signal against a background of competing noise.

Pulsar supplied their highest power transducer, the dB50, along with an Ultra 5 ultrasonic control unit. The dB50 is designed to measure up to 50 metres, so was putting a great deal of ultrasound energy into the measurement. Even so, the signal that returns to the transducer silica is very small.

Pulsar’s latest generation DATEM echo processing software identifies and dynamically tracks the material level, maintaining a link to the true material level even as it changes and other signals from the internal features of the vessel compete.