|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cables, connectors and energy chains | >Plating for harsh environments |

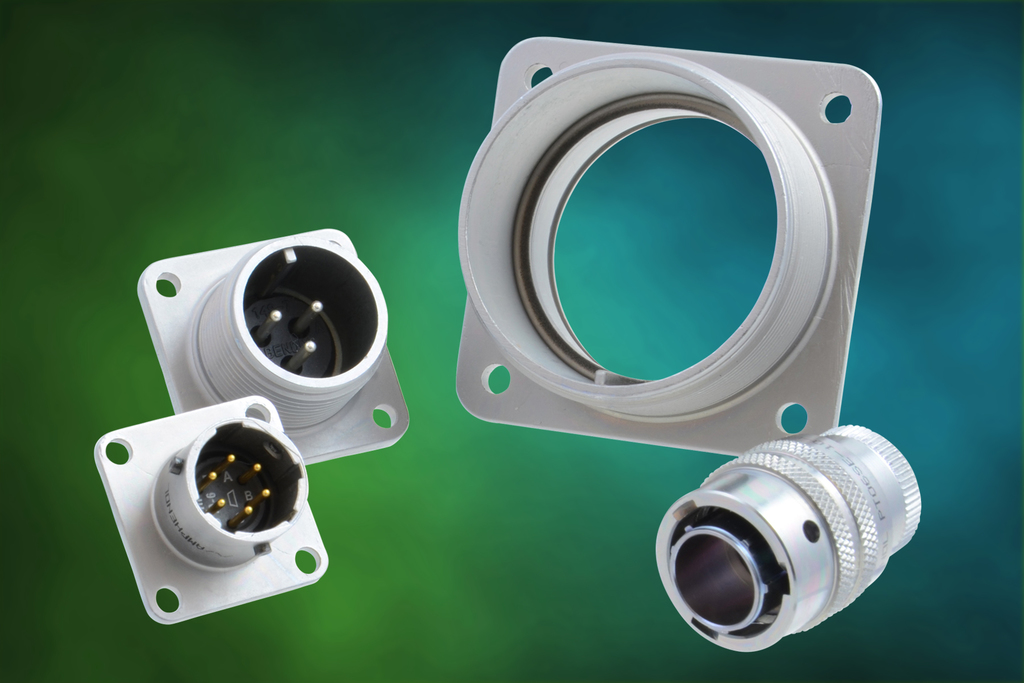

Plating for harsh environments

27 January 2016

Amphenol Industrial Products Group has enhanced its standard shell plating from standard cadmium to gray zinc over electroless nickel (Gray ZnNi) to be used for use in the harshest environments. Initially designed for use in marine applications, this plating is now utilised in military and industrial applications or where RoHS-compliant plating is required.

Amphenol’s upgraded, cadmium-free connector offers high corrosion resistance and no significant galvanic reaction when mated with leading standard market plating options.

Mark Cunningham, general manager, Amphenol Industrial said, “Standard cadmium plating can only sustain 96 hours of salt spray and is not RoHS-compliant. Electroless nickel and zinc cobalt can only reach 48 and 96 hours. Our new Gray ZnNi is rated for 500 hours of salt spray and is RoHS-compliant.”

- Enhanced heavy duty connectors

- High vibration brush terminal series

- Primary circuit power connector

- Durable datalink connector

- High pressure connectors for oil and gas applications

- Enhanced connector series

- Connecting technology for the lighting industry

- Continuous power

- Durable data link connector

- Quick connect and locking system