|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cables, connectors and energy chains | >High pressure connectors for oil and gas applications |

ARTICLE

High pressure connectors for oil and gas applications

25 January 2013

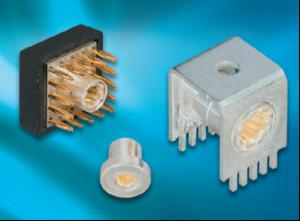

Amphenol Industrial has introduced a range of high pressure, rugged connectors designed for oil and gas downhole tools. Featuring a bi-directional psi of 20,000 the connectors are fully compatible with Kintec and GE Te

Amphenol Industrial has

introduced a range of high

pressure, rugged connectors

designed for oil and gas downhole

tools. Featuring a bi-directional psi

of 20,000 the connectors are fully

compatible with Kintec and GE

Tensor layouts. The new KTK high

pressure downhole connectors offer

a high pressure and high

temperature sealed connection

standard in the downhole industry.

These high quality, reliable connectors are suitable for use in MWD (measurement while drilling) systems, LWD (logging while drilling) tools and downhole batteries. Because these assemblies provide service companies with critical information such as drillstring rotational speed and smoothness, type and severity of downhole vibration, temperature, drill bit torque and weight and mud flow volume, reliable connectors that withstand harsh conditions are paramount in oil and gas drilling.

The connectors are suitable for applications that require lowmaintenance, accurate and reliable assemblies, while limiting risks associated with in-hole loss.

These high quality, reliable connectors are suitable for use in MWD (measurement while drilling) systems, LWD (logging while drilling) tools and downhole batteries. Because these assemblies provide service companies with critical information such as drillstring rotational speed and smoothness, type and severity of downhole vibration, temperature, drill bit torque and weight and mud flow volume, reliable connectors that withstand harsh conditions are paramount in oil and gas drilling.

The connectors are suitable for applications that require lowmaintenance, accurate and reliable assemblies, while limiting risks associated with in-hole loss.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION