|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >British manufacturing 'welded to traditional techniques' |

British manufacturing 'welded to traditional techniques'

18 March 2016

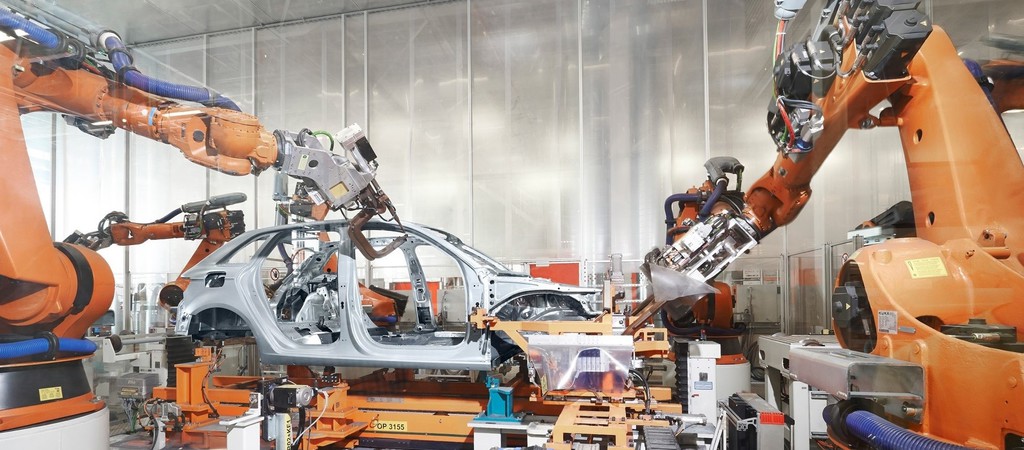

Over reliance on traditional welding and inspection techniques is harming productivity and consistency, according to a new white paper authored by Dave Halford, welding industry sector manager at Bosch Rexroth.

'Adapt and change - How adaptive control of resistance welding can cut production costs and improve product quality', explains that while welding is becoming increasingly automated, lack of adoption of new welding technology is holding industry back.

Halford said: “Adaptive welding remains a small proportion of the UK’s welding market, but its ability to improve the quality of welds and drive costs out of the manufacturing process, cannot be ignored.

“Traditional methods are prone to a variety of weld disturbances and inspection techniques take up valuable time with mixed results. By taking an adaptive approach manufacturer’s benefit from real time control and monitoring, as well as improved consistency.”

Weld testing, in particular, is seen as an area where new technology will offer significant improvements. Halford explains: “Current quality checking methods are problematic and rest on two methods, ultrasonic inspection and manually opening a proportion of completed welds. The first option requires a high level of operator training in order to get consistent results, while the second leads to scrapped parts. Real time monitoring through adaptive welding eradicates the need for these time intensive processes.”

The white paper can be downloaded fromhttps://www.boschrexroth.com/en/gb/trends-and-topics/ls6adaptivewelding

- Offshore developments

- Safe measurement, indication and control of rotational speed

- Chance to learn about Lean

- Internet of Things innovators recognised

- Inside intelligence helps boost maintenance

- Online hydraulics catalogue

- Oil contamination seen as a key cause of machinery failure

- Maintenance: an eye opener

- Prepare for new directive

- Industry 4.0 training rigs