|

Edward Lowton

Editor |

|

Equipped with 3D measurement scanner

26 April 2016

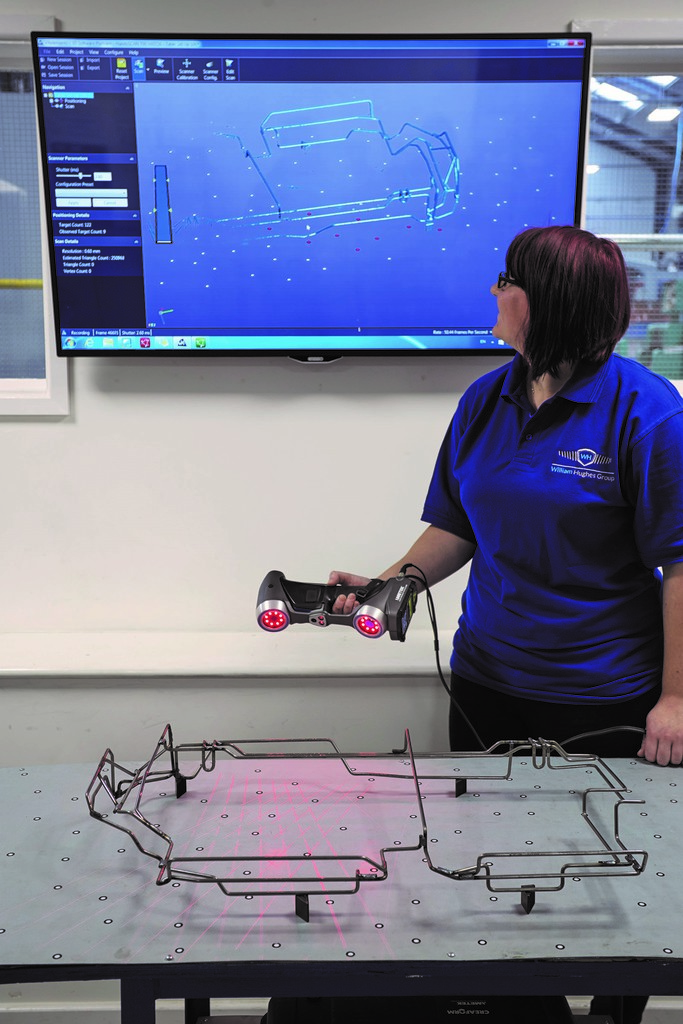

William Hughes has added the latest 3D scanner from Creaform to its test and measurement equipment to enable it to check components up to 2.5m with speed and accuracy.

David Brigg, quality manager at William Hughes, explains: “Our customers are demanding that the wire forms we manufacture meet very accurate dimensional tolerances. Whilst our previous co-ordinate measuring equipment was accurate, it was relatively slow. What we needed was a measuring device that was fast, accurate and ideally, easily transportable.”

The management team at William Hughes spent several months evaluating the latest technologies to find a machine that would meet their requirements. However, whilst there were many that would meet the need to measure components up to 2.5m, many machines were expensive and, even with articulated arm technology, not very user friendly.

“We spotted the Creaform HandySCAN 3D 700 at a trade show and were immediately impressed with its speed, accuracy and portability,” continued Brigg. “A demonstration confirmed that the scanner was ideally suited to our needs and this has now been proven in use.”

An advantage of the 3D scanner is that it can be packed into two laptop-sized bags and taken to customers’ premises, or used at the William Hughes European factory in Bulgaria. The unit is very easy to set up and use after specialist training.

As well as ensuring that products being supplied to customers are dimensionally accurate, the 3D scanner can be used to ‘reverse engineer’ components, in situations where engineering drawings are unavailable or have been lost. The scanner can also be used to check manufacturing tooling, thus speeding up development times.

- Metrology services for high precision manufacturing

- High performance springs for aerospace applications

- Strong and flexible wire assembly

- Quick with wire

- Acquisition announced

- Compression spring fatigue testing machines

- Springs: Sole supplier status

- Clean bill of health

- Double torsion springs handle car maker's needs

- More springs join range

- No related articles listed