|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >Overmoulding capability |

| Home> | Handbooks | >Manufacturing Matters Ireland | >Overmoulding capability |

Overmoulding capability

07 November 2013

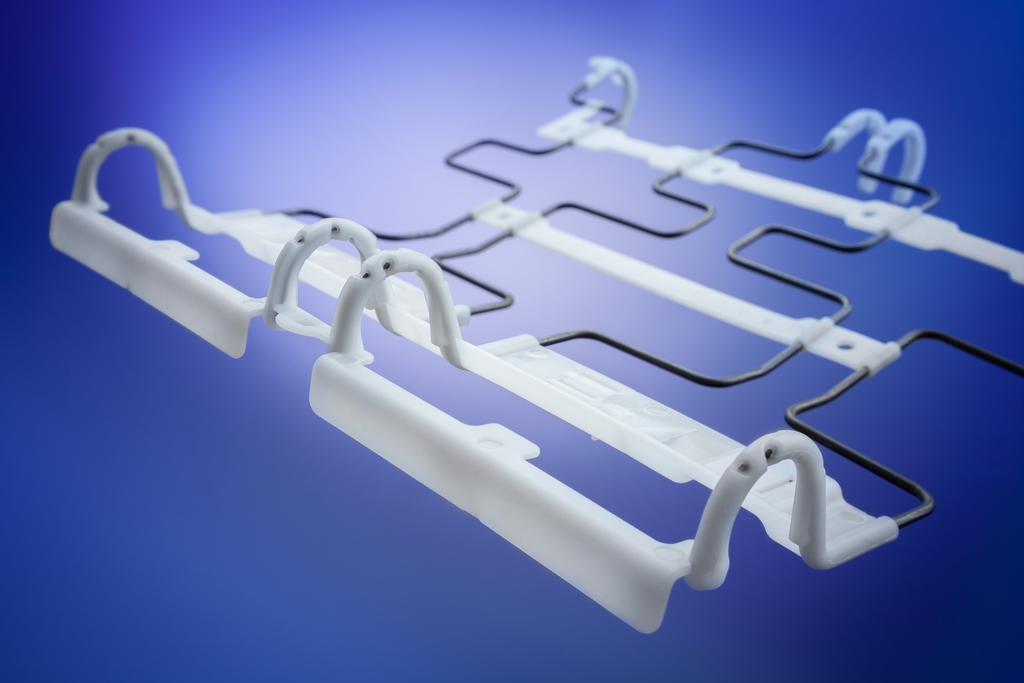

William Hughes continues to find new ways to meet its customer’s requirements for precision wire assemblies and has now introduced an overmoulding capability for wire parts.

The process dispenses with the need for metal retaining clips in assemblies such as car seats – providing an assembly that is both strong and fast to manufacture. The process can be applied to a wide range of wire assemblies and requires the wire parts to be manufactured to a high accuracy. Components are brought together using special tooling designed by William Hughes and two vertical injection moulding machines perform the moulding process to complete the assembly.

The overmoulding process allows for variations in the finished assembly – for example, in car seat assemblies retaining bars for the seat cloth can be included or where heated seats are required, connectors and cabling can be incorporated so that heating elements can be simply plugged into the encapsulated boots.

Any 2D or 3D wire form that involves twists, turns, spirals, protrusions, indentations – or just plain bends – can be accommodated.

- Quality cleaning of critical components

- Electrophoretic painting for protection of metal parts

- Specialist services

- £1/4 million investment

- Wire service

- Salt spray testing keeps a check on corrosion

- Protecting parts during storage and transportation

- William Hughes forecast to cut annual energy costs by £35,000

- William Hughes celebrates twenty years of growth and customer success at its class-leading Bulgarian factory

- Metrology services for high precision manufacturing