|

Edward Lowton

Editor |

|

| Home> | Handbooks | >IPE Ireland | >New motor cuts energy and maintenance costs |

| Home> | Plant, Process & Control | >Motors and drives | >New motor cuts energy and maintenance costs |

| Home> | Energy Management | >Motors and drives | >New motor cuts energy and maintenance costs |

New motor cuts energy and maintenance costs

30 June 2016

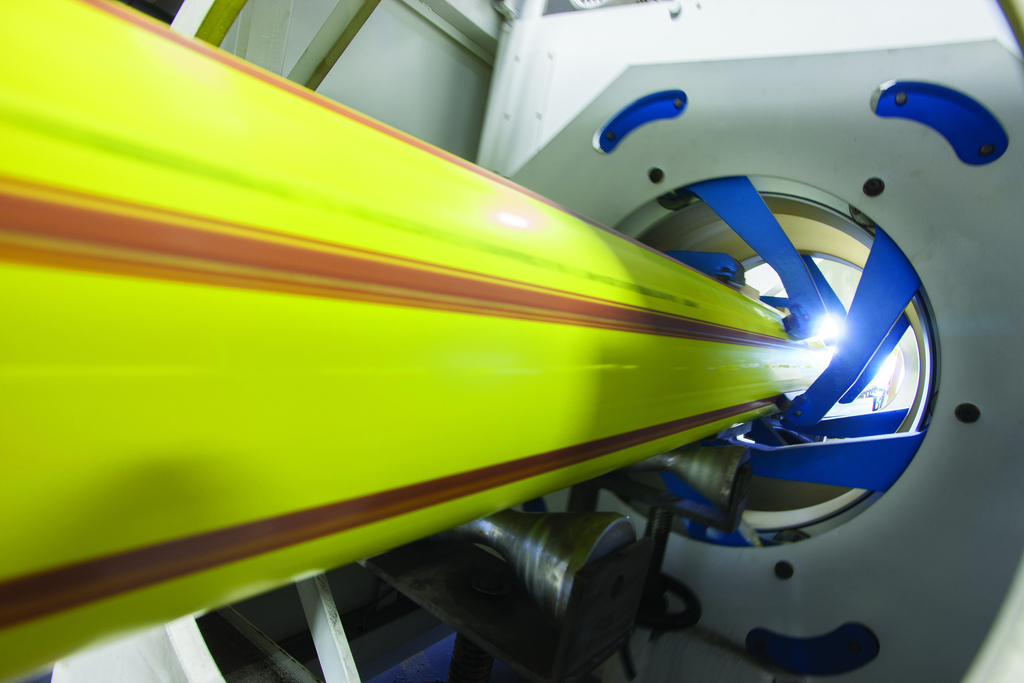

Up to 15% lower energy use and a reduction in motor maintenance costs have been achieved with the installation of an ABB synchronous reluctance motor and drive (SynRM) package on a twin extruder application.

Radius Systems’ plant in Derbyshire, UK, houses 14 extrusion lines, each of which produces polyethylene pipes. Eight lines are powered by DC motors, many of which are more than 20 years old. Line 12's 182kW DC motor was regularly failing, leading to an increase in downtime and rising maintenance costs. The company estimates that the annual static and dynamic checks, brush changes and outsourced labour costs alone are about £2000 per motor.

ABB’s authorised value provider for the area, Inverter Drive Systems (IDS), was asked to monitor the motor and was able to determine the speed range of the line’s DC motor which revealed that it was over-sized for the application and hence consuming more energy than necessary. Also, as it was 20 years old it was nowhere near the efficiency for which it was originally designed.

Energy saving bandwidth

It was estimated that potential energy savings from a SynRM package for Line 12 would be in the range from 8 to 15%, with a return on investment within two years. In addition, in excess of £2000 cost avoidance is estimated with the removal of DC motor maintenance.

“To pick an exact production run that can give an accurate energy measurement is very difficult to quantify, hence the range from 8 to 15%,” explains Rob Betts, engineering manager at Radius Systems. “The actual energy saving is dependent upon several process variables such as raw material type, different product ranges and profiles, the temperature at the die and the barrel and the general ambient environmental conditions. For instance, energy consumption is higher on a cold day as more energy is needed to warm up the process.”

Advanced technology

The SynRM is a 200kW, 1500 rpm, IE4 solution and together with the ABB industrial drive, ACS880, it offers a higher efficiency than standard AC induction motors and drives. It is also a quieter package than the existing DC motor. “SynRM has given us a reduction in noise in the production hall which is a benefit we had not expected,” says Betts. “While we have not measured the noise levels, everyone has noticed a definite reduction across the plant, which in itself is a motivational measure.”

A challenge was presented by the physical footprint of the existing DC motor. “DC motors tend to be long and thin,” explains Betts, “whereas AC motors tend to be shorter but bigger in diameter.” However, SynRM can be up to two frame sizes smaller than a conventional induction motor which is a benefit in the direct replacements of DC motors.

- Self-powered temperature transmitter

- ABB technology modernises Bruce Power nuclear units to support low-carbon energy growth in Canada

- MCERTS for pH measurement

- ABB launches new Low-Force System for ultra-thin metal strip applications

- Accurate turbidity and suspended solids measurement

- Meets strict safety standards

- ABB chosen to install high-efficiency drives and motors for DS Smith’s new recycled containerboard line in Italy

- Calculator highlights potential savings through Water technology List

- Self-powered temperature transmitter

- Pressure transmitters: Selection guide