|

Edward Lowton

Editor |

|

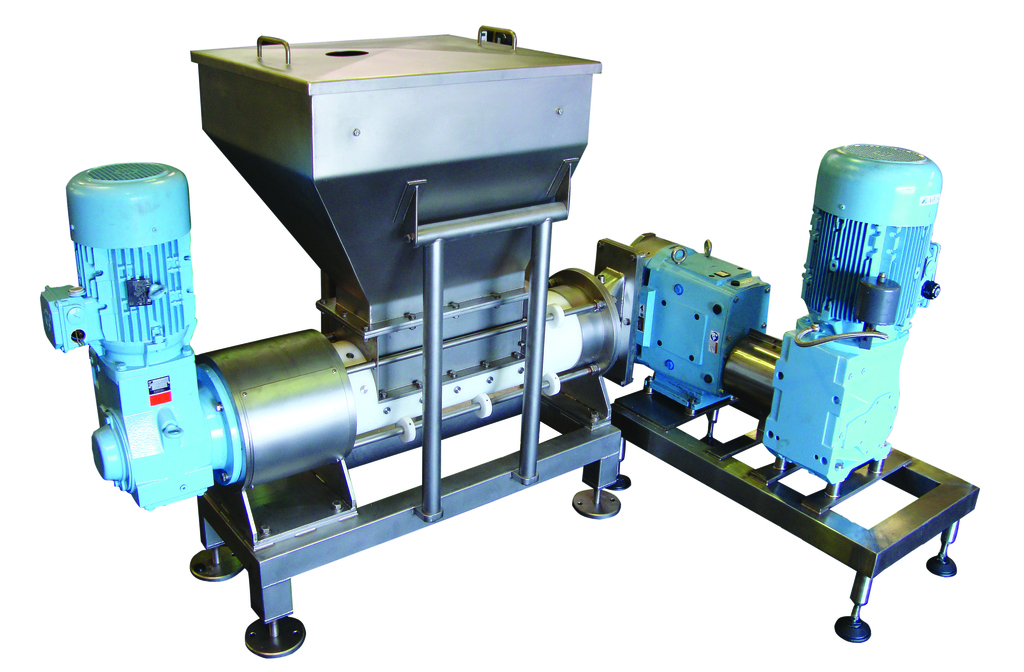

Auger feed system helps optimise output

10 February 2017

Many food processing companies are faced with handling heavy and viscous materials that cannot be moved by pumps on their own or pumps fed by hoppers. AxFlow has developed a bespoke feed system that reduces the wastage of raw materials and semi-processed foods.

AxFlow’s feed system comprises an auger into which ingredients are fed and then forces them into the pump via a screw feed. Capable of transferring media with viscosities in excess of 1,000,000cp, the system provides the transfer pump with a constant flow at a pressure no greater than 4 bar to maintain the integrity of the product. The system takes the media and moves it into the plump’s inlet port keeping it constantly full, thereby enabling the pump to transfer the media at a metered rate and pressure.

Variable speed drives can be fitted to the screw feeder and the pump to accommodate a variety of duties. Furthermore, the screw feeder can incorporate a bridge breaker for the most challenging media and the pump fitted with wide inlets to ease the flow into the pump chamber. With certain modifications the system enables users to recover and rework product that may otherwise have gone for waste.

- No related articles listed