|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >FIT for pumping |

FIT for pumping

12 January 2015

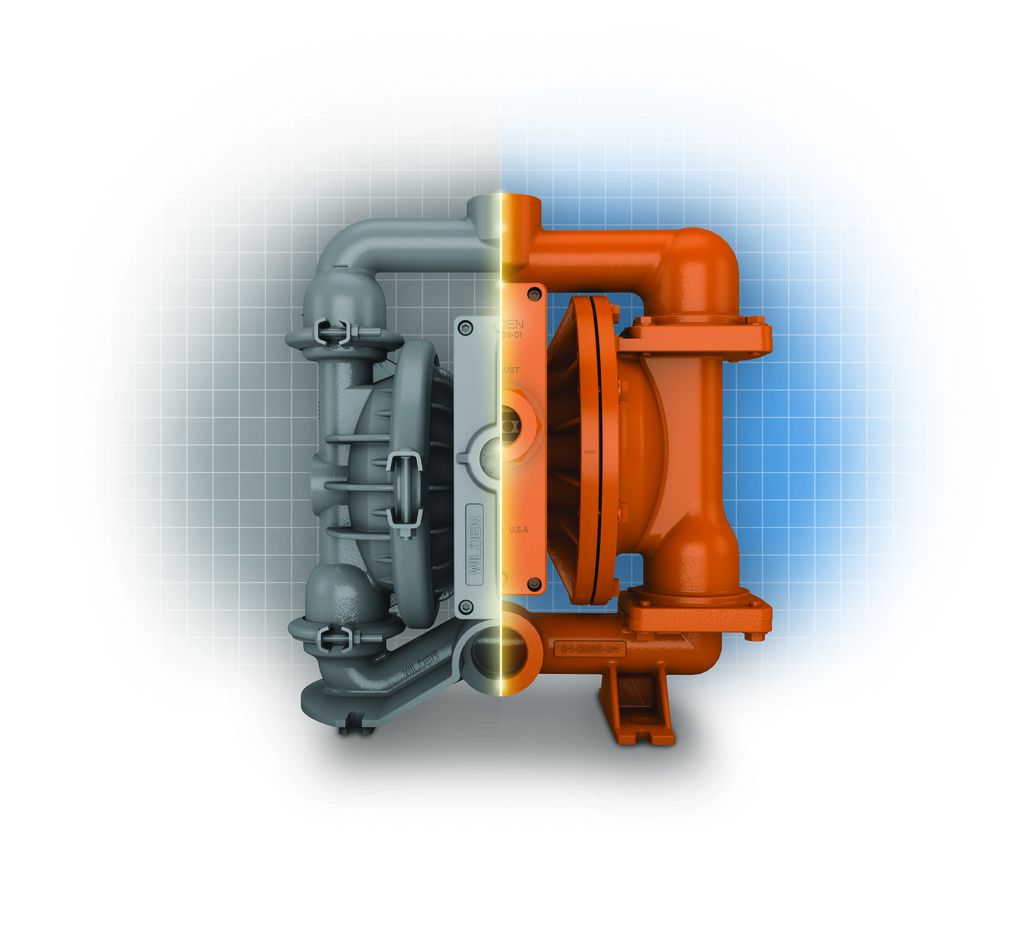

AxFlow has introduced the Wilden Advanced FIT line of air operated double diaphragm (AODD) pumps that deliver enhanced flow rates and are said to be easier to install.

The pumps ‘fit’ bolt-to-bolt and pipe-to-pipe into existing fluid handling piping systems, thereby increasing performance without the need for new piping. They have been engineered to be an easy, cost-effective way of enhancing and upgrading existing pump performance with efficient bolted product containment.

"Advanced FIT pumps represent a major breakthrough in reducing installations costs when upgrading your AODD pump as they have been designed to drop into the existing plumbing footprint without any rebuilds being necessary,” reports Peter Carfrae, AxFlow’s Wilden product manager. "FIT pumps also offer an enhanced level of performance and higher flow rates, resulting in potential energy savings and reduced air consumption.”

Key features include:

• Re-engineered fluid path increases flow rates up to 54%.

• Exact FIT from bolt-down footprint to inlet and discharge connection heights.

• Fewer fasteners and easy accessibility for faster assembly/disassembly and shorter downtime.

• Labour-saving manifold flexibility to assists in tight fitting installations.

• Fast ROI, reduced installation costs without repiping.

• Bolted configurations for efficient product containment with NPT or BSP threads or ANSI or DIN flanges.

• Available with the Wilden Pro-Flo X of Pro-Flo SHIFT air distribution systems for reduced air consumption.

• Fits competitors’ pumps footprint.

Advanced FIT pumps are available in 51 and 76mm sizes with aluminium housings and in 38, 51 and 76mm sizes with stainless steel housings.