|

Edward Lowton

Editor |

|

| Home> | Handbooks | >IPE Ireland | >Piezoelectric strain sensor |

| Home> | Handbooks | >Manufacturing Matters Ireland | >Piezoelectric strain sensor |

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Piezoelectric strain sensor |

Piezoelectric strain sensor

19 October 2017

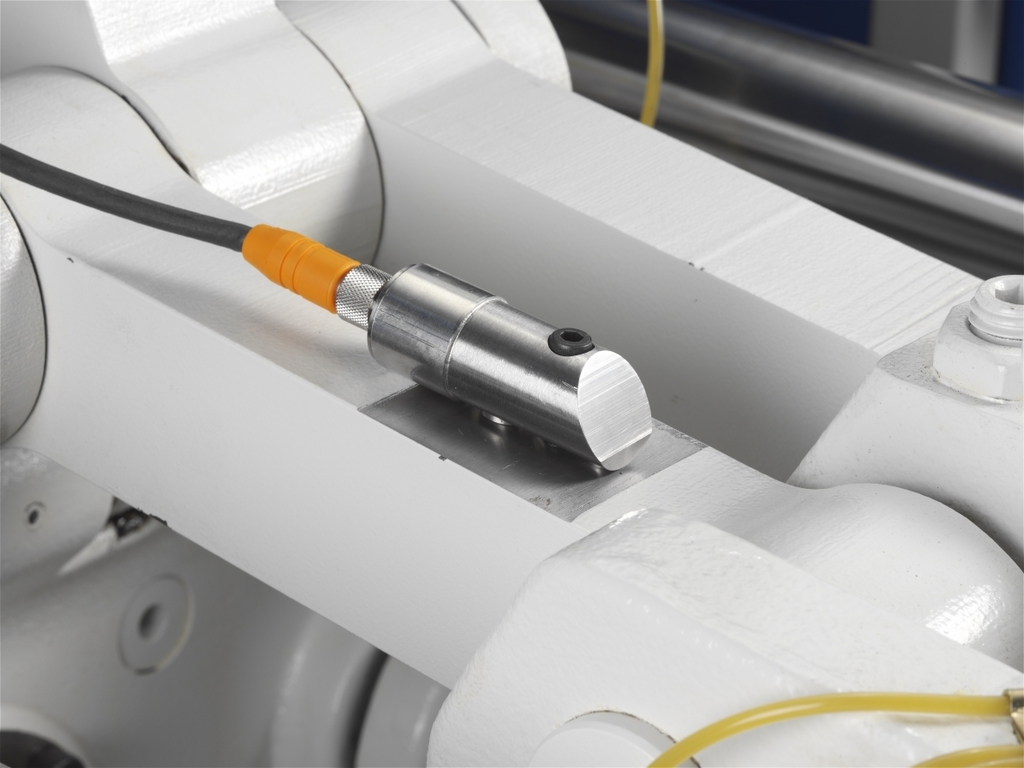

The Type 9238B piezoelectric strain sensor from Kistler Instruments uses indirect force measurement to monitor the force-proportional strain on stationary and moving machine components and structures. The integrated charge amplifier produces an industry standard 10V output, making the sensor simple to integrate into existing systems and measuring chains.

Typical applications include:

• Machine monitoring, such as protecting mechanical presses against overload

• Quality assurance in production runs for joining processes such as wobble riveting, clinching and resistance spot welding

• Monitoring machine tools, such as prompt detection of tool breakage or tool collision

The new piezoelectric strain sensor has two measuring ranges that can be adjusted to a particular value or signal curve in one hundred steps using either a dedicated ManuWare software or directly by the machine’s own PLC. When the measuring range is adjusted, the setting is stored by the integral electronics. The range can be switched remotely, even under load conditions, enabling very low forces to be accurately measured. Typical applications for the sensor are monitoring C-frame machine tools such as presses and automatic assembly machines, preventing overload of mechanical presses, quality control of riveting, clinching and resistance spot welding processes and detection of tool breakage or collision in a wide variety of machine tools.

Secured to a suitable clean, unpainted position on the machine frame by a single M6 screw, the sensor is especially easy to retrofit to almost all types of machine tools. The sensor measures dynamic and quasi-static stresses on machinery or structural surfaces using indirect force measurement. The signal can be further processed as a relative value or the sensor can be calibrated against an appropriate standard to provide absolute measurements in N or kN.

The parameters of the integral charge amplifier are configured using the included ManuWare PC program. For test purposes the ManuWare software can also transmit digital measurement data (at a rate <20Hz) for display on the screen. The robust construction provides a IP67 rating making the sensor suitable for use in dirty and wet environments. Kistler says advantages of piezotechnology compared with foil strain gauge technology are high sensitivity, high overload resistance, virtually unlimited service life and high load cycle stability.

Cable connection is by a single M12-8-pin socket, mounted either on the end or upper face of the sensor, using screened cables available with straight or right-angled connector. The excitation voltage and measuring cycle control, range switching and communications interface data are carried to the sensor via the same cable used to transmit the measurement signal. Where the integral charge amplifier is not required, the similarly specified Type 9232A may be used.

Although designed for real world, industrial applications, the new strain sensors are equally suited to research and development applications requiring ease of installation and precision combined with versatility and reliability.

- Combined pressure and temperature sensor for composite moulding

- Kistler maXYmos provides quality assurance

- Sensing support for Industry 4.0

- Networked SCP

- Cost effective simple joining processes

- Innovative shear design

- Rotating torque sensor has wireless signal transmission

- Cutting costs

- X-Y monitoring system

- Joining module