|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Bearing rotates quickly, wears slowly |

| Home> | Efficient Maintenance | >Bearings | >Bearing rotates quickly, wears slowly |

Bearing rotates quickly, wears slowly

10 April 2017

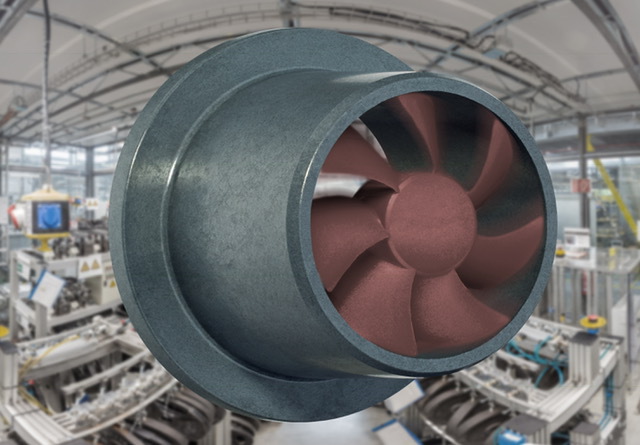

As a result of continuous research and development, igus has a new material for very high speeds in continuous operation. The glider L350 is suitable for fans, blowers or electric motors and, in rotational tests in the igus test laboratory in Cologne, the material proved its full potential against its metallic counterparts.

Robert Dumayne, dry-tech director, igus, explains: “iglidur L350 is the perfect alternative to oil-impregnated sintered bearings, both for initial installation and for retrofit."

Friction and wear are critical issues, especially where permanently fast rotations prevail. iglidur L350 is said to score highly when compared with solutions such as metallic sintered bearings due to higher resilience against impacts and edge pressure. Tests showed a three-fold reduction in wear at speeds of 1.5m/s. While sintered bearings reached their limits at still higher speeds, igus says the coefficients of friction and wear for iglidur L350 plain bearings remained constantly low.

Key characteristics of the new material are its low thermal expansion, even at temperatures to 210°C. Due to the low moisture absorption properties, the material is also safe in different media. Plain bearings made of iglidur L350 can be calculated and ordered online; the material is also available for the development and production of customer-specific geometries and bearing solutions.

- Real twister

- Harnessed dress-packs boost cable protection for welding robots

- Cable range extended

- For reliable operation of vertical farming systems

- Maintenance-free plastic components

- Online 3D printing service

- Maintenance-free PRT slewing rings

- Smart plastics for industry 4.0 condition monitoring

- Link to video

- Quick installation