|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Retort furnace for powder metallurgy and additive manufacturing |

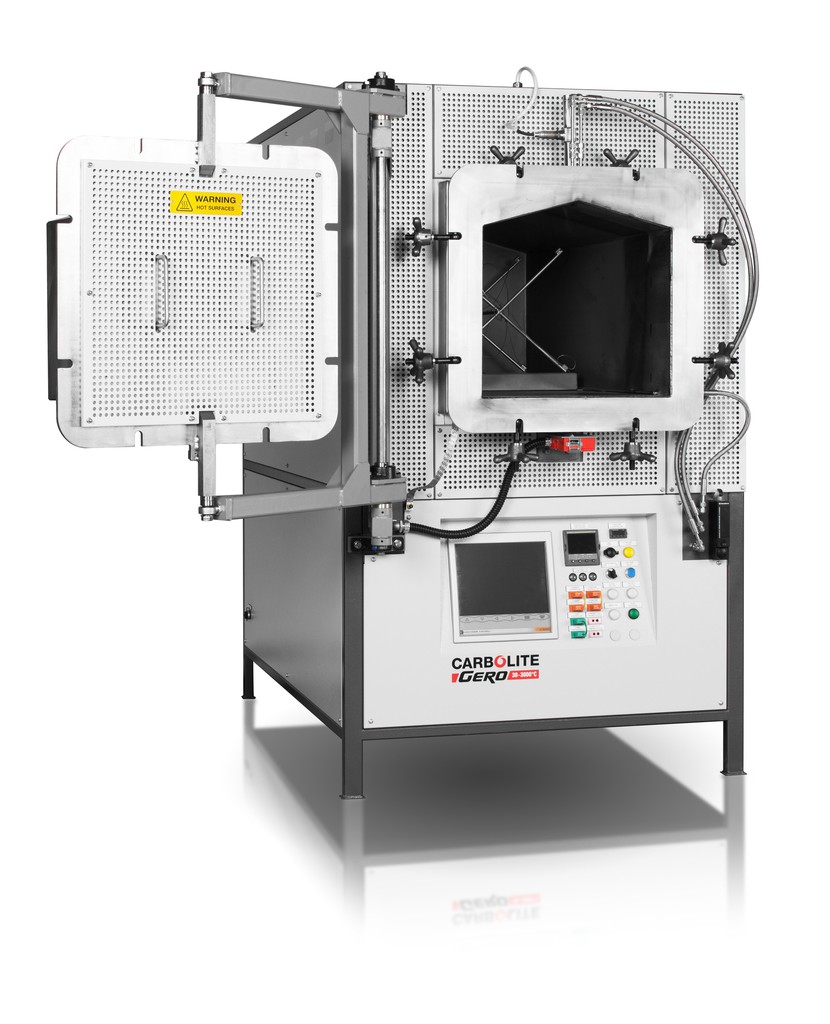

Retort furnace for powder metallurgy and additive manufacturing

01 June 2017

Carbolite Gero is known for the design and manufacture of laboratory/industrial ovens and furnaces ranging from 30 to 3000°C. The company has considerable experience in the heat treatment of MIM parts and is a furnace supplier for additive manufacturing (AM) in the field of powder metallurgy.

For AM applications, the GPC 12/300B furnace with an Inconel retort has a maximum operating temperature of 1100°C and has been designed for applications where a modified atmosphere and temperature uniformity are required for the sintering of components from AM machines using metal powders.

The O2 content (which can be less than 30ppm) can be continually monitored by an optional probe in the gas outlet, while larger models can accept 2 or 3 build plates. In addition, the shielding gas (nitrogen or argon) is monitored by a digital flowmeter. For AMS 2750E applications the GPC 13/300B can meet Class 2, Instrumentation Type B.

For MIM applications, CARBOLITE GERO supplies furnaces to debind (catalytically or thermally) and sinter the formed part; this process can either be carried out in two separate furnaces or in a combined furnace (model PDS 120 MO/14).

- Furnace and press

- Heat-treatment for fencing weapons

- Rotating tube furnace with easy-to-remove work-tube

- Sophisticated thermal processing

- Custom oven meets capacity challenge

- Oven accuracy key to product testing

- Furnaces process high-tech ceramics

- Heat treatment

- Rotating tube furnace

- Heat-treatment furnaces