|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process heating | >Short wave system |

Short wave system

21 January 2014

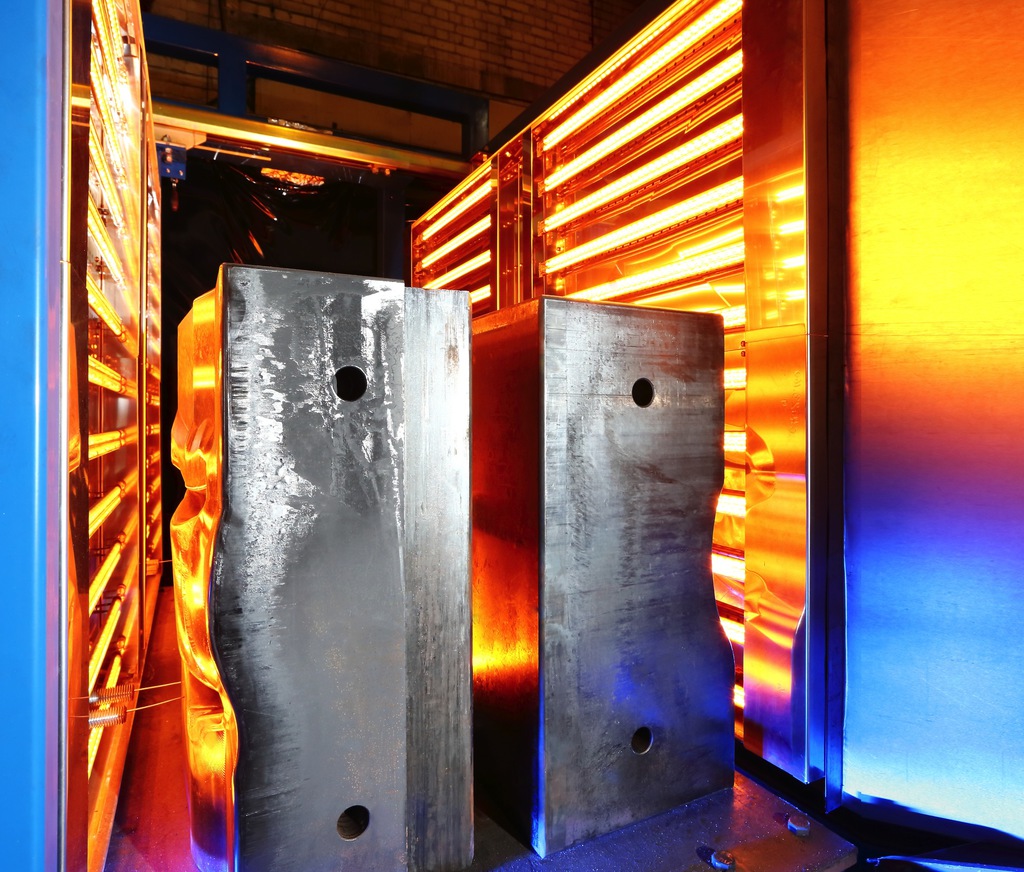

Short wave infra-red emitters from Heraeus Noblelight have allowed Mettis Aerospace to reduce the time required for the heating of tools and dies used in the manufacture of high specification titanium aircraft components to one seventh of the heating times required by a previous gas system.

The short wave system installed consists of two 72kW infrared cassettes, each mounted on an aluminium vertical profile frame. The two frames are positioned on either side of the table used to support the tools, which can be heated in pairs or singly, with heat applied from one side only or from both sides.

During heating, a pair of thermocouples measures the temperature of each tool face and this measurement is then used to automatically regulate each cassette’s emitters constantly from 0-100% to maintain the set temperature with optimum energy consumption, maximising the system’s efficiency.

- IR heater helps with hose fitting

- Infrared drying boosts corrugator capacity

- Air rinsing for jam pots

- Queen’s Award For Enterprise winner

- Carbon infrared emitters halve drying times for screen-printed T-shirts

- Infra-red heating system

- Spirit firm toasts new cask end process

- Carbon infrared heating system

- Line speed boosted

- Infrared emitter