|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Powerful synchronous drum motor |

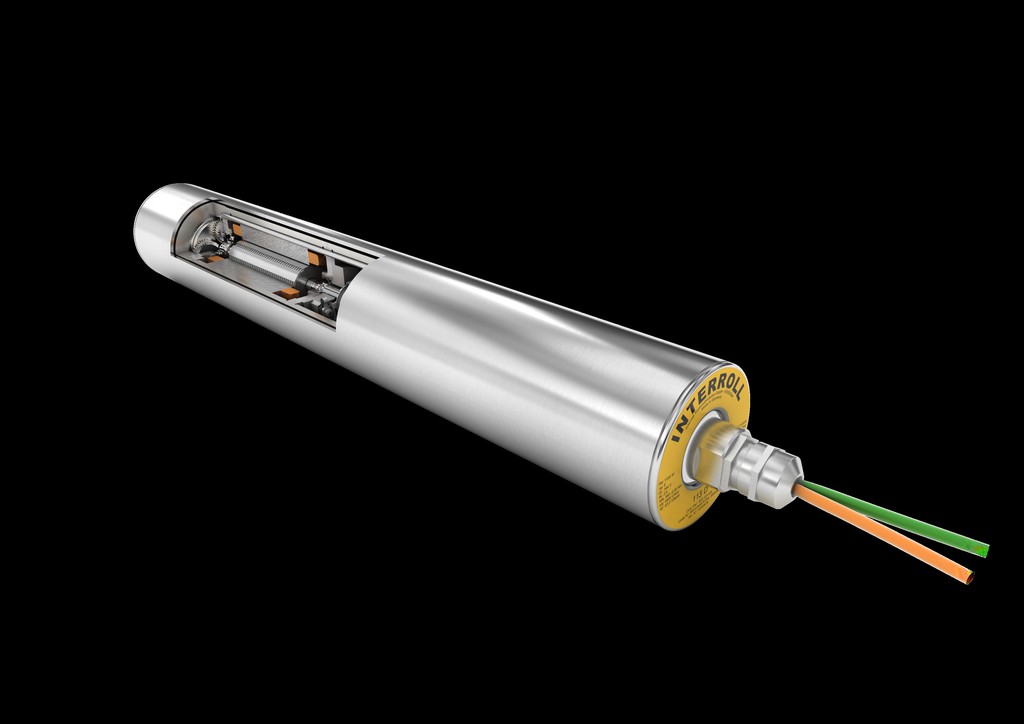

Powerful synchronous drum motor

10 July 2017

A powerful synchronous drum motor for belt conveyor systems has been introduced by Interroll and has a proven output of up to 1.1KW, a particularly high torque to 100Nm and extremely high belt tension.

Interroll says that this drive solution offers the food and pharmaceutical industries an ultra-hygienic and energy-saving option. Its compact design supports smaller turning diameters and makes it possible to convey smaller items and handle a wide range of products on one single system.

The new motor allows for belt speeds to 3.34m/s, has a low operating temperature and effortlessly tackles steep acceleration and braking ramps. Made entirely from stainless steel, the construction and design of the completely enclosed drive meets the highest hygiene standards and are based on the EHEDG (European Hygienic Engineering & Design Group) guidelines.

These motors display a loss of performance of just 9%. A planetary gear that is made from hardened steel transfers 92 to 95% of the available power directly to the relevant conveyor system, and is said to reduce the energy requirement when compared to alternative drive systems.

The drive, which is available immediately, is suitable for a high throughput of material to be conveyed.

- Roller conveyor keeps cycling gear on track

- Drive solution enhances roller conveyors

- Efficiency improvements

- Synchronous drum motor

- Modular conveyor platform

- Speed control

- Interroll intensifies exchange of expertise with digital channels

- New profile for driving belts

- Powerful drum motors

- Interroll's lean, clean, conveying machine