|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Back by popular demand |

Back by popular demand

07 August 2017

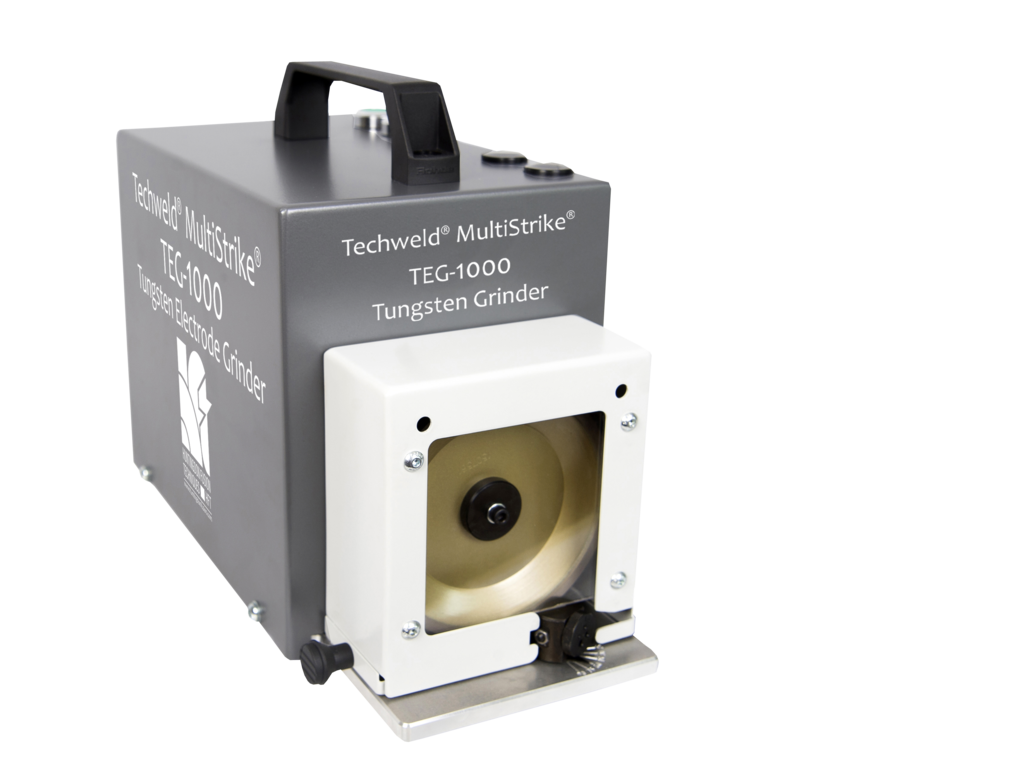

In response to customer demand Huntingdon Fusion Techniques has re-initiated the manufacturing of the retired TEG-2 Tungsten Electrode Grinder under the new name of TEG-1000.

The use of the TEG-1000 Grinder will give repeatable Tungsten Electrode points every time, enabling consistent repeatable arc performance and welding results. Sizes 1.0 to 3.2 mm can be ground as standard, with other sizes catered for on request.

Savings can be achieved because of the increased life of properly ground Tungsten Electrodes. With the special collet accessory, shorter Tungsten Electrodes can be held, significantly increasing the length of life of each Tungsten Electrode before it is discarded.

TIG welding requires Tungsten Electrodes to have perfectly ground and polished tips. HFT’s TEG-1000 provides these, time after time, to exactly the same size and shape. The diamond wheel grinds the Tungsten Electrodes’ longitudinally, preventing arc flicker or wander caused by circumferential lines or ridges found on electrodes, which have been ground incorrectly.

With Tungsten Electrodes ground and polished, mechanised welding can produce identical, repeatable results every time. With manual welding, the shape of the Tungsten Electrode is just as important. With a correctly shaped tip, the arc can be precisely positioned with none of the preferential arcing experienced when using poorly shaped manually ground tips.