|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Cut costs, not corners |

Cut costs, not corners

24 July 2018

Welders are always looking for time and cost savings when pipes need to be purged of oxygen before, during and after welding (weld purged). Weld purging large diameter pipework fabrications and pipelines not only carries a large price tag when it comes to time, it can also cost a lot in inert gas.

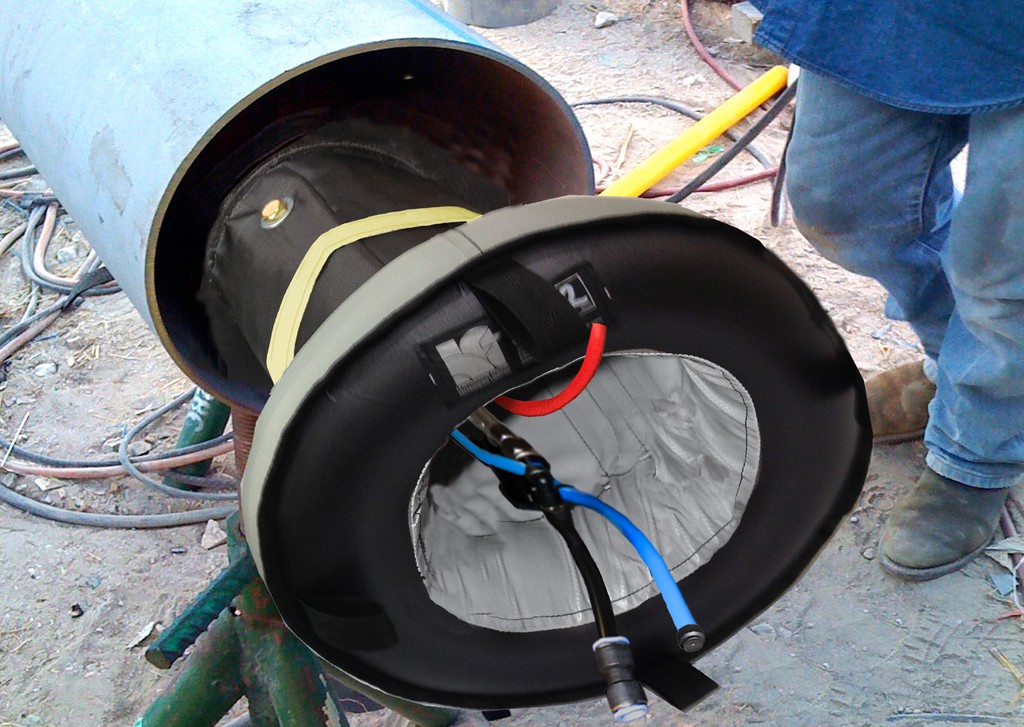

Weld purging specialists and developers Huntingdon Fusion Techniques HFT manufacture QuickPurge Tube, Pipe and Pipeline Weld Purging Systems. QuickPurge® Systems are designed to be inflated inside of the pipe, drastically restricting the volume that needs to be purged, so much so that the Systems pay for themselves in just one or two welds.

A Customer in the USA said: "What an enormous saving in waiting time for our welders. Normally we wait several hours for our 30" stainless steel pipe joints to be purged and now we can start welding in under 10 minutes."