|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Additional material joins knife edge roller range |

Additional material joins knife edge roller range

21 January 2018

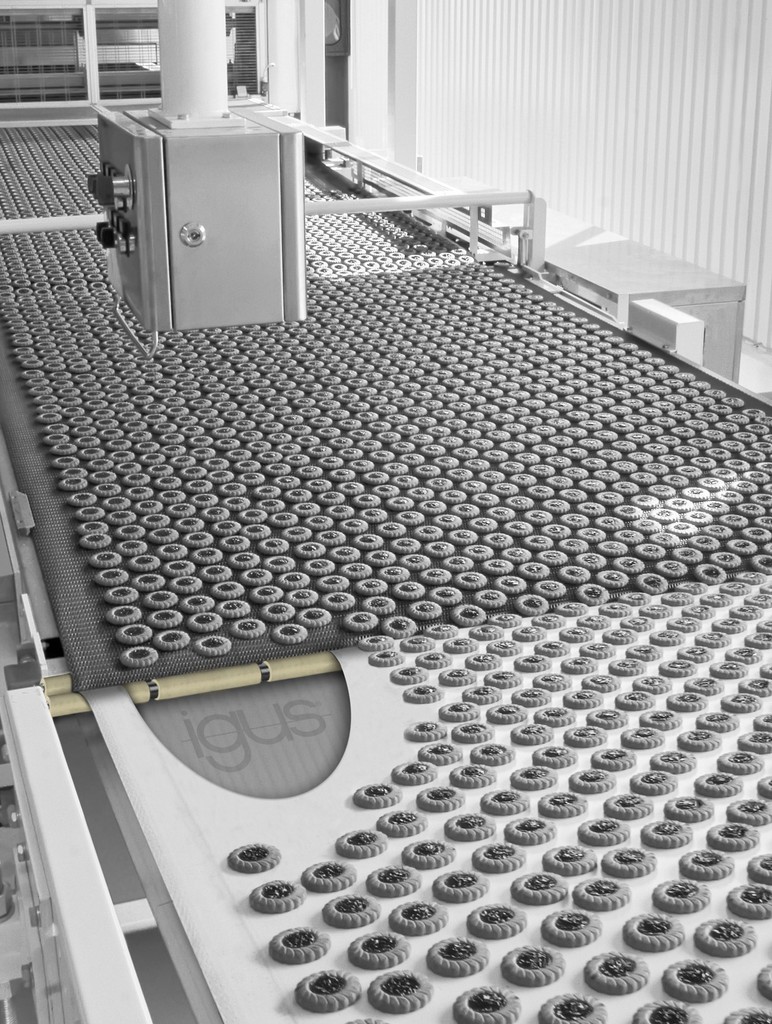

igus has added iglidur H1 material to its knife edge roller range for conveyor applications for higher travel speeds, thus expanding its range to include a total of four materials.

AnotherAPlastic knife edge rollers allow smooth, lubricant-free transfer of transported goods onto downstream conveyors. Due to their compact design and relatively tight radii, they are often found in food production machines, bottling lines and packaging systems as well as in point-of-sale units in supermarkets.

igus says the iglidur H1 rollers are characterised above all by a better performance at faster conveying speeds and have a long service life, even at higher temperatures. In addition, the chemically resistant material is suitable for applications where the rollers are exposed to aggressive cleaning agents.

The knife edge rollers are available in a selection of different lengths and diameters. In addition to iglidur H1, knife edge rollers are made of three other igus engineering plastic materials: iglidur P210, which is extremely resistant to wear and characterised by low humidity consumption; FDA compliant iglidur A180 for low to medium loads is suitable for high humidity applications that come into direct contact with foodstuff and suitable for temperature to 90°C; and iglidur A350, which is blue in colour for visibility within food manufacturing, for medium to high loads and temperatures to 180°C.

- 25 year celebration

- Smooth sailing for superyachts

- Service robots with low-cost robotic joint

- Tribo-tape liner range expanded

- Handles sharp changes in temperature

- Open for entries

- Harnessed dress-packs boost cable protection for welding robots

- Long-lasting solutions for e-chain applications

- Industry 4.0 – Realising the Revolution

- 3D-printed injection mould tools