|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Processing times cut |

Processing times cut

01 March 2018

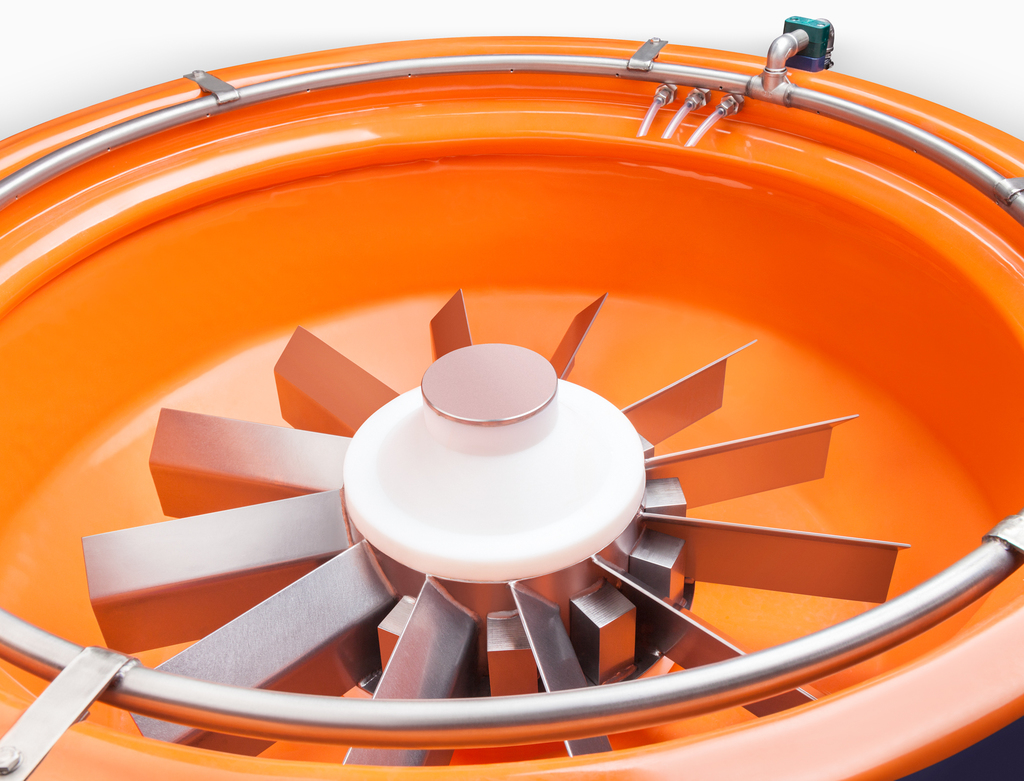

For the efficient surface finishing of high value work pieces like blisks for airplane and land based turbines, Walther Trowal has redesigned its CM vibratory system. It ensures that the work pieces receive a uniform, homogeneous high quality finish with absolutely repeatable results.

To date the surface finishing of blisks was done manually with grinding disks and other manually operated tools. Due to the “human factor” the quality of the final finish could greatly vary between work pieces. Frequently, it could even happen that certain surface areas were not finished at all.

For the consistent and high quality finishing of circular high value components Walther Trowal redesigned the rotary vibrator “CM” in close cooperation with leading turbine manufacturers to make it more suitable for treating all kinds of turbine components.

Starting with an initial surface roughness of Ra = 4 to 5 µm, the desired finishing results are achieved within about five to six hours whereas the manual finishing of blisks can take several days.

- Coater for small batches

- Walther Trowal: New modular controls enhance the process safety of mass finishing applications

- Cleans greasy parts

- Finishing machines on show at the Deburring Expo 2017

- Gentle smoothing of guide vanes

- High gloss polishing of ceramic surfaces

- Coater for small batches

- Gentle finishing of extremely thin work pieces

- Efficient coating of O-rings

- Plastic grinding media for mass finishing tasks