|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cables & Connectors | >Connection considerations in PROFINET applications |

| Home> | Production Engineering | >Cables, connectors and energy chains | >Connection considerations in PROFINET applications |

ARTICLE

Connection considerations in PROFINET applications

14 October 2019

icotek outlines points to consider when making the connection between cable shield and equipotential bonding bar in PROFINET applications.

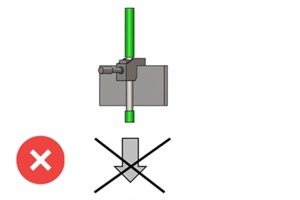

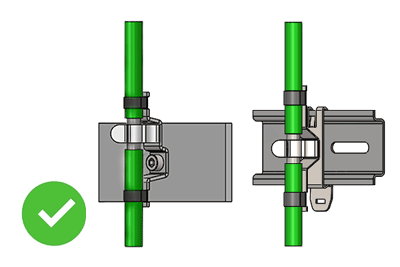

The PROFINET installation guidelines point out that PROFINET must be fixed / strain-relieved cables above and below the shield connection. The cable shield must not be used for strain relief. The cable shield is not suitable to absorb mechanical tensile forces. Otherwise it is very likely that the cable shield will be damaged under tensile load. The cable jacket (outer sheath) is suitable for strain relief.

When establishing the shield connection, note the following:

- Remove the PROFINET cable jacket only for the required connection surface. The PROFINET cable is susceptible to mechanical damage in the area where the jacket has been removed.

- Be careful not to damage the shield when stripping off the PROFINET cable jacket.

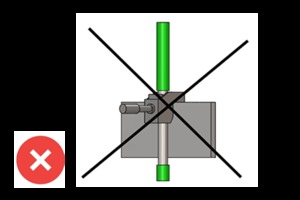

No tensile load

- Do not use the shield connection as a strain relief location. This would reduce the contact quality between the shield and the equipotential bonding bar.

Exception: installation components specifically designed for this type of application.

- Secure the PROFINET cable above and below the shield connection position. The PROFINET cable can thus be protected against bending. Pay particular attention to strain relief if the cable is exposed to motion.

- Use only connection components that are suitable for the diameter of the stripped cable.

- Do not attach the equipotential bonding bar to coated surfaces. Galvanised or chromed surfaces, for example, are well suited. Use tin-plated, galvanised or otherwise galvanically treated installation material which is protected against corrosion and establishes a permanent high quality contact.

Source: https://www.profibus

MORE FROM THIS COMPANY

- EMC shield clamps for use on C-rails

- Hybrid cable entry possible with new grommet

- QTMB grommet: One size fits all

- Tool-free mountable cable entry plates

- icotek grommet with staged membrane rings

- Long life lamps

- Cable grommets

- Hygienic design for cable entry plate

- Single cable entry plate

- M25 cable gland in hygienic design

RELATED ARTICLES

OTHER ARTICLES IN THIS SECTION