|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Industry 4.0 | >ELESA expands castor wheel range |

ELESA expands castor wheel range

06 February 2023

MOBILITY IN industrial environments is a factor that can significantly affect people's health and safety in the workplace on the one hand and efficiency and productivity on the other.

Offering solutions with high quality standards for the materials used and for the guarantees on performance and mechanical resistance is a necessary condition for satisfying the technical needs of the market. But a diversified range, developed to respond to different sectors, from factory equipment to furniture, from the food industry to the medical, from the handling of heavy loads to "ESD protected" environments is certainly a strong point our customers can count on

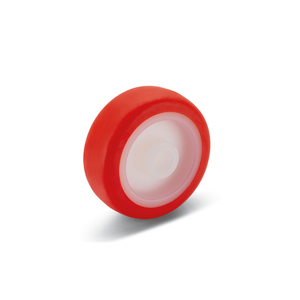

It is with these purposes in mind, that the range of ELESA industrial wheels expands and specialises more and more. The company's new RE.F1 wheel is made of blue injected polyurethane with a technopolymer central body, available in diameters of 80 mm, 100 mm and 125 mm, dynamic carrying capacity from 750 N to 1800 N in the versions with fixed plate support or swivel in galvanized steel, with or without brake.

The reduced hardness of the coating (Shore A for the new RE.F1 against the Shore D of the bestseller RE.FF), makes it suitable for agile overcoming of obstacles, guaranteeing at the same time excellent rolling resistance and silence during handling as well as good tearing resistance. RE.F1 series is suitable for use in environments with the presence of atmospheric agents, alcohols and glycols, weak organic and mineral acids, water and saturated vapour.

RE.C6 castors for the general public with injected polyurethane coating and technopolymer central body are available with diameters of 40 mm, 50 mm and 60 mm and dynamic carrying capacity from 400 N to 700 N and can also be supplied with sheet metal steel supports for light loads (RE.C6-C) or as twin-castors (RE.C6-G).

The excellent resistance to frequent washing makes it suitable for environments where it is necessary to guarantee hygiene in institutional and industrial environments even in the presence of humidity and chemical agents.

- Self-sanitisation against bacteria and fungi

- Redefining hygiene with Elesa's Hygienic Design line

- Magnets for temporary fitting

- Elesa Vacuum Cups shake up the sector!

- Elesa will be exhibiting at Southern Manufacturing and Electronics 2023, Farnborough.

- Vibration damping the ELESA way

- Eleroll with it – modular roller tracks

- If you can handle the heat …

- Combined hinge/cut-off for packaging safety

- Elesa expands further into ATEX-compliant hydraulic components

- Introducing Industry 4.0 to SMEs

- Enhance maintenance practices

- Digital transformation: Customer insight matters

- IoT digital experiments as a service

- Smarter maintenance: Paper available

- Condition monitoring & Industry 4.0

- Smart data collection

- Mechanised welding, cutting and Industry 4.0

- Tomorrow’s tech is here today

- The business value of Industry 4.0