|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Industry 4.0 | >Enhance maintenance practices |

Enhance maintenance practices

27 March 2018

Idhammar Systems aims to bridge the gap between manufacturing today, and the smart factory of tomorrow by providing straightforward, practical technology solutions to improve process, bottom line and employee satisfaction through their OEE, CMMS and World Class Manufacturing (WCM) systems.

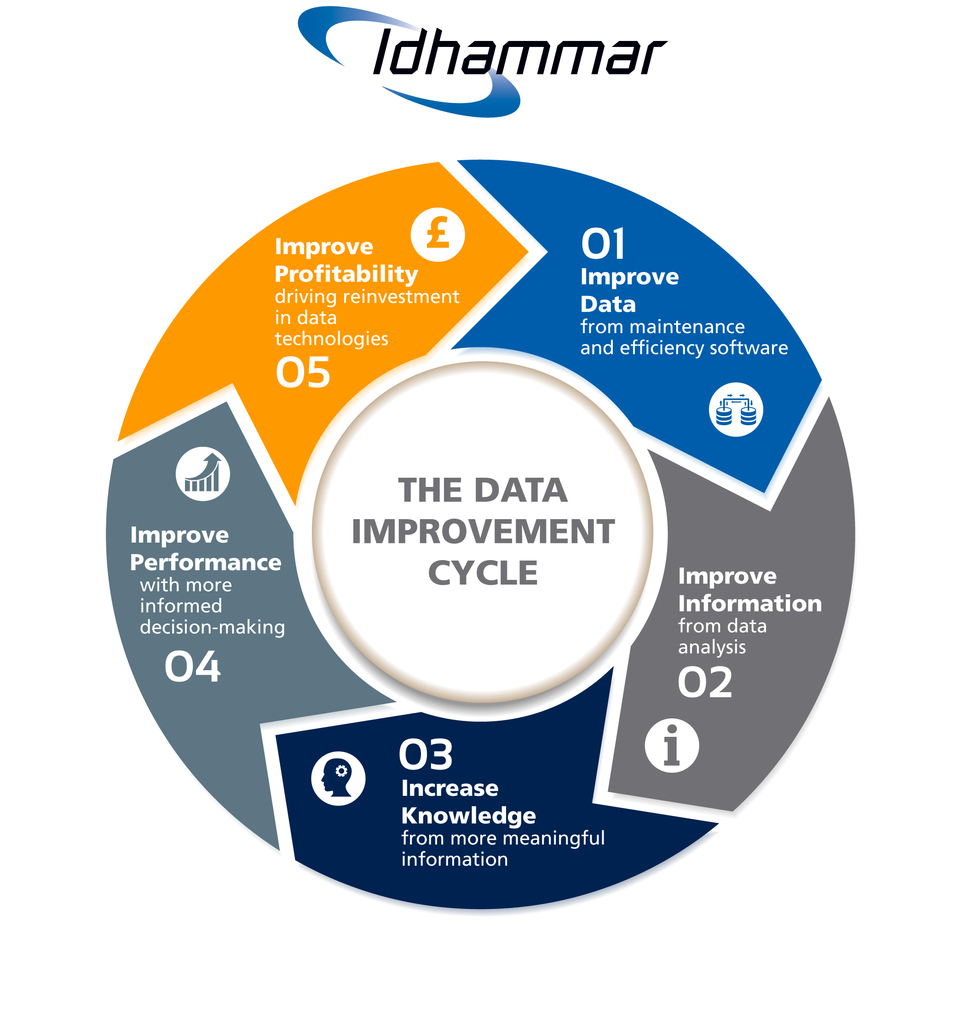

A crucial decision for UK manufacturers in 2018 is to invest in efficiency technologies and software to streamline and improve manufacturing data and production line performance. Idhammar says the vastly improved quality of data that a manufacturing organisation will be able to gather and analyse with Idhammar solutions will kick-start a cyclical process of data driving knowledge, in turn driving profitability and reinvestment.

Easy to use yet powerful, Idhammar MMS is designed to enhance organisations maintenance practices and minimise downtime. Idhammar OEE enables drill down analysis to quantify even the smallest opportunities to help make every second of production count and steer continuous improvement.

Stand H17-460

- Idhammar launches World Class Manufacturing at Maintec 2015

- Fresh features

- Visit Stand H17-460 at MACH to start your journey towards IR4 with Idhammar Systems

- Launching new software suite

- Software for those at the sharp end

- Idhammar REPORTS = Greater control on asset performance

- Useful forum for sharing best practice

- Reduce your carbon footprint with Overall Equipment Effectiveness

- How to improve your Manufacturing Operations...

- Latest CMMS

- Introducing Industry 4.0 to SMEs

- Digital transformation: Customer insight matters

- IoT digital experiments as a service

- Smarter maintenance: Paper available

- Condition monitoring & Industry 4.0

- Smart data collection

- Mechanised welding, cutting and Industry 4.0

- Tomorrow’s tech is here today

- The business value of Industry 4.0

- Micropositioning solutions