|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Seals and sealants | >Food-grade seals |

Food-grade seals

14 January 2019

As exclusive provider for Freudenberg Sealing Technologies' food and beverage related products in the UK, Dichtomatik UK now offers the company's Simmerring seals in two new materials.

Designed for the reliable sealing of rotating shafts, Simmerring can be found in millions of applications and machines across a myriad of sectors. The product is said to be flexible, highly loadable and very dependable. Freudenberg Sealing Technologies has now further developed Simmerring for use in the process industry, by making it available in food-grade materials.

Dichtomatik says conventional PTFE shaft seal rings soon reach their limits at high rotational speeds and pressures, which typically leads to leaks and other seal failure modes. In addition, the company says that, to date, it has not been possible to use Simmerring in the food industry as its PTFE materials have not been approved for food-related applications. Rising to the challenge, Freudenberg Sealing Technologies set about developing two new Simmerring materials especially to meet the requirements of process industries such as food and beverage, and pharmaceuticals.

Simmerring products in the B2PT design are now produced from a newly developed material, Quantum PTFE F18245, and a housing manufactured from 1.4571 (V4a) stainless steel. Here, the PTFE deployed has been created specifically for direct food contact. Approvals are anticipated shortly under FDA 21 CFR 177.1550 und EC 10/2011. The B2PT design, which is suitable for applications up to 10 bar, can also be adapted to suit specific customer requirements.

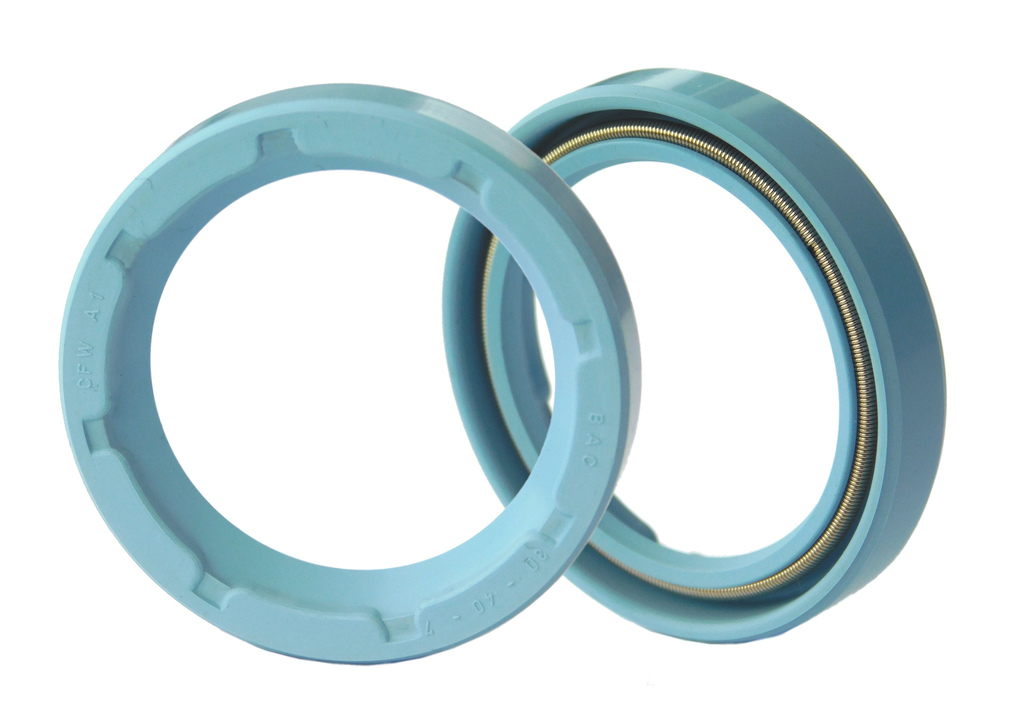

A further innovation from Freudenberg Sealing Technologies is the Hygienic BlueSeal, which is said to be the first dead-space-free version of the Simmerring. Suitable for food and beverage industry applications, this hygienic shaft seal ring has a forward-mounted lip featuring geometry that allows no hard-to-clean areas, thus preventing any bacteria build-up and subsequent process contamination. The Hygienic BlueSeal can be used in low-friction and low-pressure (<1 bar) applications. The latter is made possible thanks to targeted adjustments in geometry. Hygienic BlueSeal also makes use of the Quantum PTFE F18245 material.

The second new material development for Simmerring is 75 Fluoroprene XP 45, which aids secure attachment to metal. This highly fluorinated material already has the required approvals and certificates under EC 1935/2004, EC 2023/2006 and FDA 21 CFR 177.2600.

Any seals manufactured from Fluoroprene XP are said to stand out for their excellent, broad resistance. The material combines the performance characteristics of FKM and VMQ in non-polar media (greases, oils and hydrocarbons), with the qualities of EPDM materials in polar media (water, acids and lye). Thanks to the complete encasement of the Simmerring with 75 Fluoroprene XP 45, complemented by a stainless steel spring, the product is suitable for use in a wide range of food and beverage applications.