|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Labelling, marking and barcoding | >Ice Vector establishes Clearmark's foray into pallet labelling |

| Home> | Handling and Storing | >Labelling, marking and barcoding | >Ice Vector establishes Clearmark's foray into pallet labelling |

Ice Vector establishes Clearmark's foray into pallet labelling

04 August 2021

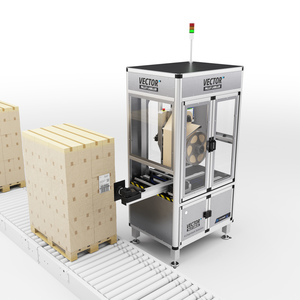

AT THIS year’s PPMA Show, digital coding company, Clearmark will celebrate its 20th anniversary by making its foray into the logistics labelling space with the launch of the innovative ICE Vector pallet labelling system.

The ICE Vector brings to the marketplace a new high performance, low maintenance tertiary option that is exceptionally easy to integrate with line and warehouse management systems. ICE Vector completes Clearmark’s coding portfolio, enabling customers to benefit from joined-up coding solutions across their primary, secondary and tertiary operations paving the way for the factory of the future.

Special engineering differentiators makes the ICE Vector a high-performance system including: climate controlled cabin to ensure consistent print quality; robust long-reach cartesian-style arm guarantees GS1 specification label placement on all pallet configurations; a dual operator interface for continual working during ribbon/label reel changes; intelligent I/O system to seamlessly communicate with today’s highly automated warehouses.

The launch of ICE Vector on Stand D72 is timely with warehouses accelerating their investment in intelligent automation, mitigating supply chain issues (exacerbated by Brexit and the pandemic). As more products flow through supply chains at speed, warehouses call for smarter, faster, self-reliant systems to meet demand.

The ICE Vector Pallet Labelling System promises to deliver an attractive ROI for any high-throughput operation looking to automate its pallet labelling process, from food, beverage and pharmaceutical factories, to supply chain and logistics operations. Powerful, reliable performance and seamless integration with factory warehouse management systems (WMS) are the bedrock of the ICE Vector advantage. The ICE Vector is powered by the ICE Vulcan print engine – the fastest in its class. With a compact footprint of just 1125mm x 875mm and operational speeds to 100 pallets an hour, it can perform up to four label applications per pallet, with two adjacent sides to conform to GS1 specifications for SSCC pallet labelling or three sides for customer specific applications.

The ICE Vector is designed as a robust, fully enclosed system, thanks to a pneumatic guard protecting the print engine from dust and environmental conditions. Optimum conditions within the enclosure are maintained via a thermostatically controlled heater (as standard) with the doors only opening at the point when the ICE Vector is ready to label.

With a label arm reach of 650mm out of the enclosure via a sturdy 2 axis cartesian guided motion control system, label placement is accurate and repeatable on a wide range of pallet configurations.

For more information about the Vector, visit: https://www.clearmark.uk/products/labellers-lpa-uk/vector-pallet-labeller?utm_source=PR&utm_medium=Digital

www.clearmark.uk/vector

- Training: Back on track

- Delivering seamless e-Commerce print-on-demand solutions

- Digital Catapult selects net zero startups

- Cloud-based order management solution

- UV air disinfection unit

- Bridging the gap between academia and industry

- Blueshift unveils AeroZero lightweight thermal protection tape for enhanced safety in battery systems

- Smart factory investment at critical stage

- Investment allowances, energy costs and R&D top list of priorities for manufacturers, says survey

- Inspiring the next generation of Welsh engineers