|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Industry 4.0 | >Strengthening materials-handling performance through smarter analysis |

Strengthening materials-handling performance through smarter analysis

19 February 2026

In high-demand materials-handling operations, structural failures, flow blockages and unplanned shutdowns can bring production to a standstill. By applying advanced modelling, digital twins and predictive acoustic analysis, IDECO is helping operators resolve complex mechanical issues and keep bulk-handling equipment running safely and efficiently, explains Laura Villa.

THE CALL came in urgently: a bucket wheel stacker/reclaimer had suffered structural failure where the gantry connects to the traveling system. For the maintenance team, it was a nightmare scenario - a critical link in the materials handling chain, suddenly compromised.

The cause? A missing internal diaphragm at a section reduction point. Somewhere along the design chain, this small but crucial detail had been overlooked - and the consequences were far from small.

Digital twins reveal hidden structural weaknesses

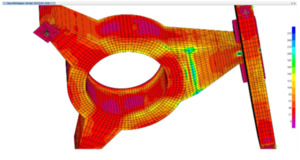

IDECO's response demonstrated the power of modern computational analysis. Using Finite Element Method (FEM) software - specifically SAP2000 and its MEANS (Mechanical Analysis System) - the engineering team created a digital twin of the structure, stress-testing it under various load conditions.

The static analysis pinpointed exactly where forces were concentrating and why the structure had buckled. But here's where engineering creativity entered the picture: adding the missing internal diaphragm wasn't practical on installed equipment. The original geometry was locked in.

Instead, IDECO designed an external reinforcement system that achieved equivalent structural resistance to what the missing internal diaphragm would have provided, without requiring extensive disassembly or modification of the existing structure. The solution was documented in complete workshop drawings, ready for implementation.

The modification restored structural integrity, extended service life, and - perhaps most importantly for plant managers - brought the equipment back into compliance with Eurocodes and ISO standards while minimising inspection downtime going forward.

A hopper geometry mystery

Blockages are the bane of bulk handling operations. For one client, the scenario had become dangerously routine: the coal hopper would gradually clog, material would overflow, and operations would halt while crews manually cleared the obstruction. Production losses mounted with each incident, and safety concerns grew as workers repeatedly entered confined spaces.

The problem seemed straightforward: coal wasn't flowing properly through the chute. But identifying the root cause required understanding material behavior at the particle level.

IDECO's approach began with comprehensive material analysis, determining the coal's angle of repose, particle size distribution, density, and abrasiveness. These aren't just academic numbers; they're fundamental to predicting how bulk materials actually behave under real operating conditions.

Redesigning the discharge system

Armed with this data, the team turned to Discrete Element Method (DEM) simulation using Newton Professional software. This powerful tool models thousands of individual particles, simulating how they interact, compress, and flow under gravity. The simulation revealed what visual inspection couldn't: the hopper's wall angles completely disregarded the coal's natural angle of repose and its complementary angle. Additionally, chute sections were undersized, creating restriction zones where material would inevitably bridge and rathole.

After modeling the material properties and simulating flow dynamics, IDECO analysed and optimised the hopper geometry. The validation process included checking calculations against dedicated and appropriate standards, not just simulation for simulation's sake, but engineering rigor backed by established design codes.

The result was a completely redesigned discharge system based on these studies, with geometry specifically tailored to the material's actual behavior.

Key takeaways for preventing bulk-handling breakdowns

Across these examples, several principles emerge that can help operators avoid costly breakdowns:

Start with the material, not the machinery. Understanding your specific commodity's angle of repose, particle size distribution, density, and abrasiveness isn't optional - it's fundamental to reliable bulk handling. Generic specifications based on "similar" materials aren't good enough when blockages cost thousands per hour.

Validate designs against actual behavior. DEM simulation isn't just for new installations - it's equally valuable for troubleshooting existing systems that never quite worked as intended. If you have recurring flow problems, the geometry is probably fighting the material's natural characteristics.

Invest in predictive analytics before you have a crisis. Vibro-acoustic monitoring, thermal imaging, and geometric scanning pay for themselves many times over by preventing catastrophic failures. The technology has matured to the point where even mid-sized operations can implement meaningful predictive programs, especially through remote service models that don't require on-site specialists.

Don't assume original designs are optimal. Even well-engineered systems may have overlooked details (like that missing diaphragm) or may be operating outside their intended parameters years into service. Periodic FEM verification can identify structural vulnerabilities before they become emergencies.

Consider hybrid build-and-monitor models. Advanced diagnostics don't require continuous on-site expertise. Remote monitoring with specialist interpretation, as IDECO demonstrates, delivers expert-level maintenance intelligence and design quality at a fraction of traditional costs. For operators managing multiple sites or remote locations, this model is transformative.

Treat data as a strategic asset. Every vibration reading, every temperature profile, every load cycle generates information about your equipment's condition and remaining life. Organisations that systematically collect and analyze this data gain compound advantages in reliability over time.

Ensure compliance, not just function. Adherence to Eurocodes, ISO standards, and CE/UKCA directives isn't bureaucratic overhead, it's engineering discipline that ensures safety and reliability. When failures occur, compliance documentation also protects against liability.

Laura Villa is CEO of IDECO Heavy Equipment

For more information:

Tel: +36 70 522 1235

- Proposals for packaging producers to pay full recycling costs

- Expanding drilling possibilities with CoroDrill Dura 462

- Digital corrosion and erosion monitoring solutions

- Parents influence young people's view of engineering

- Manufacturing activity weakens but order books improve, says CBI

- AMRs: the safe choice for the warehouse

- Veotec manufactures HVAC solution for Ingersoll Rand

- Midlands manufacturers complain of being locked out of NHS PPE contracts

- PartsForMachines launches dedicated charity programme

- Hydro has made progress in securing safe and stable operations following cyber attack

- Technology and Open Standard data enabling smart maintenance

- Broadband sensors: Pinpointing leaks in compressed air systems

- Mechanised welding, cutting and Industry 4.0

- Tomorrow’s tech is here today

- Investment in infrastructure, innovation and people

- Getting to 4.0 – one hard-won gain at a time

- Digital transformation in the chemical industry: White paper

- Digital industry around the world

- Guidance via AR

- How machine learning is transforming predictive maintenance