|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Compressors meet university challenge |

ARTICLE

Compressors meet university challenge

04 March 2013

The physics department at the Delft University of Technology (DUT) conducts quantum mechanical experiments.

The physics department at the

Delft University of

Technology (DUT) conducts

quantum mechanical experiments.

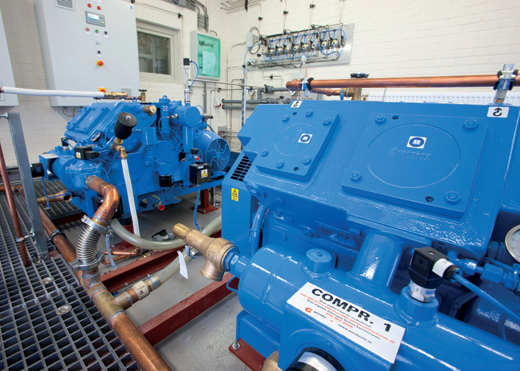

Two Reavell H5417 compressors help recover up to 95% of the helium used in its research work.

As well as reducing raw material costs, the compressors' regulatedspeed technology and monitoring software is helping to lower the department's operating costs.

The compressors, with custom built control and monitoring were developed by the Dutch Reavell partner Geveke and are configured to compress the gas to 200 bar pressure, which is stored in 250+ storage tanks.

The regulated-speed technology enables the DUT to fine tune compressor running hours, reducing overall energy consumption. The volume in the low-pressure buffer balloons can alter according to the DUT's liquid helium usage, so the Reavell/Geveke package was built to include control software, allowing compressor use to be tailored to needs.

Oil and moisture separators in the compressor ensure clean, dry helium.

Jelle Haanstra from DUT explains: "It is important that the helium gas is as clean as possible. Oil and moisture can affect the integrity and safety of our experiments. We are very pleased with the quality and reliability of the high pressure gas produced by the Reavell machines."

Two Reavell H5417 compressors help recover up to 95% of the helium used in its research work.

As well as reducing raw material costs, the compressors' regulatedspeed technology and monitoring software is helping to lower the department's operating costs.

The compressors, with custom built control and monitoring were developed by the Dutch Reavell partner Geveke and are configured to compress the gas to 200 bar pressure, which is stored in 250+ storage tanks.

The regulated-speed technology enables the DUT to fine tune compressor running hours, reducing overall energy consumption. The volume in the low-pressure buffer balloons can alter according to the DUT's liquid helium usage, so the Reavell/Geveke package was built to include control software, allowing compressor use to be tailored to needs.

Oil and moisture separators in the compressor ensure clean, dry helium.

Jelle Haanstra from DUT explains: "It is important that the helium gas is as clean as possible. Oil and moisture can affect the integrity and safety of our experiments. We are very pleased with the quality and reliability of the high pressure gas produced by the Reavell machines."

MORE FROM THIS COMPANY

- Did we celebrate autonomous quality inspection too soon?

- Managing your business and supply chain COVID-19 responsibilities

- Alva Industries appoints Thomas Bergan as COO

- AITT is excited to exhibit at IMHX 2025

- Tackling energy blind spots

- Manufacturers take action to tackle growth-harming skills shortage

- Spring into Jefferson Tools’ seasonal Tool Up offers

- Keeping track of critical alarms during a pandemic

- Make UK to provide critical cyber security to home workers

- Food for thought

OTHER ARTICLES IN THIS SECTION