|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Interroll introduces new vertical crossbelt sorter |

Interroll introduces new vertical crossbelt sorter

04 August 2021

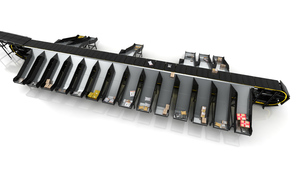

SPACE-SAVING, energy-efficient and easy to maintain, the new MX 018V Vertical Crossbelt Sorter from Interroll is designed to make it easier for system integrators and their customers to enter the world of automatic crossbelt sortation solutions.

Above all, courier and parcel service providers, e-commerce providers and logistics service providers gain the ability to handle a high variety of goods in a space-saving, gentle and energy-efficient manner via a single technical infrastructure with a high number of end points. At the same time, users benefit from the performance and economic advantages offered by Interroll's proven, mechanically driven crossbelt sorter platform.

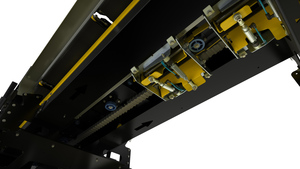

For the new MX 018V Vertical Crossbelt Sorter, which replaces the previous ST 6130 Vertical Crossbelt Sorter, the conveying speed of unit loads has been increased to up to 1.8m/s compared to 1.6m/s. In addition, the maximum extension length has been increased from 80 to 180m. With the new sorter, high throughput rates of up to 14,000 unit loads per hour can be achieved and goods weighing up to 35kg can be transported. In the process, the sorter handles a wide variety of different sorted goods – from cartons, parcels, maxi letters, and mailing bags to polybags and more. Use of energy-efficient geared motors is said to enable lower energy requirements compared to conventional sorter drives.

Interroll sorter control on request

If desired, the new MX 018V Vertical Crossbelt Sorter can be commissioned both quickly and safely, using a modular and autonomous machine control system from Interroll as a plug-and-play solution, and connected to the respective on-site goods management system by the system integrators.

Steffen Flender, managing director of Interroll Automation GmbH, explains: "The linchpin of the new solution is the benefit it offers our customers. That is why the new MX 018V Vertical Crossbelt Sorter is based on our modern crossbelt sorter platform, which is already used in the MX 025H Horizontal High Performance Crossbelt Sorter. In this way, our customers and the users benefit from, among other things, proven technologies, short delivery times and fast spare parts supply as part of the Interroll Lifetime Service. At the same time, the system can be seamlessly adapted to user-specific requirements thanks to its modular expandability. One example is the optionally available Top Loader, which is based on the innovative infeed conveyors for crossbelt sorters."

Today, about 500 sorters from Interroll are in use worldwide at companies such as Amazon, DHL, FedEx, UPS, Hugo Boss, Inditex (ZARA), Zalando, Swiss Post, Austrian Post and China Post. The company believes a key reason for this success is the basic mechanical principle of these automatic sorting systems. The number of electronic components in Interroll's sorter solutions has been kept as low as possible. The design principle thus ensures maximum availability, a long service life, minimal operating costs and short payback times.

For more information, visit: www.interroll.com

- Space-saving solution

- Tapered elements secured from inside

- Interroll's lean, clean, conveying machine

- Converts pallet racking into dynamic carton flow store

- Fully automated sorting system

- Integrated drive solutions

- Interroll expands belt curve offering

- Modular drum motors

- Motorised drive solutions

- Modular conveyor platform