|

Edward Lowton

Editor |

|

Food Grade Lubricants: Increased Performance and Safety

02 October 2018

The thinking used to be that you only needed to use H1 products 'above the line' and that for 'below the line' applications you were safe with industrial (NSF H2) lubricants.

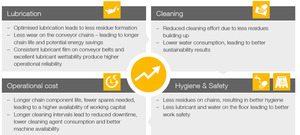

This thinking has since changed and it is now accepted that the only way to prevent any contamination from industrial lubricants is to remove non-food-grade products completely and only use H1 products across a site, but there is a misconception that food-grade lubricants don't perform as well as industrial lubricants, and that they can even compromise the performance of equipment. The good news for maintenance managers is that this is not true, in fact technical advances in the industry have shown that H1 lubricants can deliver the same if not better performance than conventional industrial gear oils and can be used effectively in extreme temperature environments.

Although not all food, beverage and pharmaceutical companies are required to use H1 lubricants, the benefits far outweigh the cost of having to recall products due to contamination issues and the potential damage that could do to a brand. By converting to an all food-grade site not only saves money, but drives food safety - it's a win-win.

- Bearing grease condition analysis for wind turbines

- The right services for higher availability

- increased output; reduced costs

- Designed for high temperatures

- Eco-compatible multi-purpose grease for rolling and plain bearings

- Eco-compatible open gear lubricant

- KlüberConsult – saving energy and reducing CO2

- Klüber Lubrication shows commitment to Yorkshire

- Leader in speciality lubricants

- New universal sliding fluids to minimise noise in cars

- No related articles listed