|

Edward Lowton

Editor |

|

Remote monitoring in the oil industry

25 October 2018

Automation of oil rigs is gathering pace. Robotics means that a typical well needs only five on-site workers, down from a peak of what some industry observers called "a fat and bloated" level of around 20. And as the manning drops, so does the need for remote monitoring of assets.

An agreement concluded by Yokogawa with Statoil is to jointly develop a field wireless system for monitoring of plant noise levels in real time at Statoil’s plants and upstream (exploration and production) facilities, as part of Statoil’s Wireless Noise Surveillance Project (WiNoS).

In plants, there are many different noise sources, and the noise that is produced can have a harmful effect on workers, impairing their hearing. As noise levels often vary considerably, periodic monitoring with sensors must be done in real time and at multiple locations so that plans can be drawn up for protective measures such as restricting the amount of time workers spend in noisy work environments and requiring that they wear hearing protection.

Data acquisition systems at production sites must be able to measure and collect not only flow rate, pressure, temperature, and other kinds of production data, but also environmental data such as the concentration of a gas. Wireless technology is well suited for use with such systems. For such applications, field wireless systems are superior to wired systems because it is easier to collect data from sensors spread out over a wide area, sensors can be installed in difficult-to-wire locations, and wiring costs are lower, even with systems that have many sensors.

By introducing this system, Statoil will be able to obtain real-time noise information during work in noisy areas and use the data for better risk control of the noise exposure of personnel.

The system will help Statoil in risk management of noise exposure and achieve compliance with the OHSAS 18001 specification. Yokogawa will provide its technology and products to build the ISA100 Wireless communication system, and Statoil will determine the overall system specifications and conduct field tests. Technologies contributed by other Norwegian companies and research institutes will be also used to develop the sensors and data visualization graphics.

In real time, this data will be superimposed on a map of the plant that can be viewed in a central control room or via a cloud service. The data can be saved and accessed at any time for analysis.

Remote pump monitoring

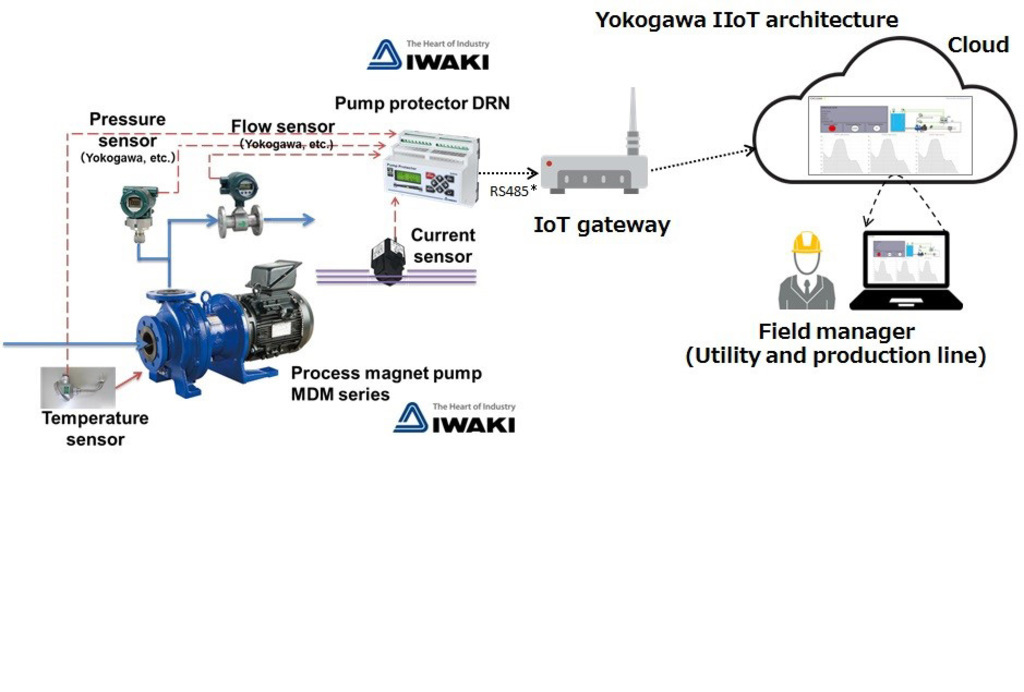

Elsewhere, and with wider applicability, Yokogawa has begun working with Iwaki on a proof-of-concept (PoC) test for a remote pump monitoring service. This will use an Industrial IoT (IIoT) architecture that is currently under development.

Iwaki is Japan’s leading manufacturer of chemical and pharmaceutical pumps. By partnering with this company, Yokogawa will gain access to its abundant know-how and expertise and thus be able to rapidly evaluate the market potential for such a service.

Yokogawa and Iwaki will jointly conduct a PoC test of a service for remotely monitoring the operating status of Iwaki magnetic drive pumps which are widely used in oil, chemical, pharmaceutical, and food plants for the transport of various types of fluids. The centrifugal pump in which the rotational force of a motor is transmitted to an impeller using magnetic force, eliminating the need for a seal to prevent the leakage of fluid. The wetted part is coated with either Teflon or silicon carbide and is chemical resistant. With this service, operating data such as the current being drawn by a pump, pump discharge pressure and flow rate, temperature of the conveyed liquid, and tank empty/not empty status will be collected via an Iwaki pump protector DRN and transferred to the cloud using the IIoT infrastructure that Yokogawa currently has under development, and will be available for remote access from any location by a facility manager. With the ability to remotely monitor the operating status of the pumps at a facility, the facility manager will be able to detect problems early on and consult with staff at the head office to decide on comprehensive and appropriate countermeasures.

Pump manufacturers will be able to use this service to ensure the timely maintenance of their customers’ products in the field. With this service, it will be possible to remotely monitor the operating status of multiple pumps, and a warning message can be emailed to the facility or maintenance manager to ensure a timely response whenever a set threshold is exceeded.

With the IIoT architecture that Yokogawa is developing, an IoT gateway device will receive sensor data via a low power wide area network (LPWAN) or some other wireless link, or via an analogue/digital communications interface. Once in the cloud, this data can then be accessed using a cellular or fixed line network. Yokogawa aims to create a system that simplifies the process of connecting to sensors and other instruments and transferring that data to the cloud. With plug-and-play functionality, device detection and configuration will be done automatically, and other functions will ease the tasks of data transfer, remote control, and alarm notification. This service is expected to be compatible with pumps from manufacturers other than Iwaki, providing they use the DRN pump protector.

Through the PoC test, the market potential will be evaluated, and the companies plan to look into the feasibility of speeding up its commercialisation by offering it based on a subscription model. This is a system in which fees are paid depending on the usage period.

- Conveyor and chain lubrication solutions for food and beverage applications

- Award winning Hydro Lubricants

- Emerson confirm event partnership for Maintec 2019

- Providing practical solutions to everyday maintenance challenges

- Slow Speed Bearing Inspection with Ultrasound

- Western Business Media wins three major awards

- Kimberly-Clark, SSG Insight and Pruftechnik confirm participation for Maintec 2018

- Leading trade body BSIF announces support for Maintec 2018

- IP&E Awards shortlist announced

- DipCAM qualifications boost Direct Air’s compressed air expertise

- Three minutes with Bosch Rexroth

- Smart monitoring for maintenance and part quality

- Modern Maintenance Matters

- Predictive maintenance pushes technology boundaries

- The patchy case of maintenance in the Food & Drink industry

- Five essential health & safety updates for business leaders in 2018

- Adapting the supply chain to maintenance needs

- Bosch Rexroth confirms event partnership for Maintec 2018

- Leading trade body BSIF announces support for Maintec 2018

- PTC and InVMA supporting a winning project at Birmingham City University Innovation Fest