|

Edward Lowton

Editor |

|

| Home> | Handbooks | >Maintenance Management Guide | >Selecting the right industrial lubricants |

Selecting the right industrial lubricants

11 May 2023

MANY PEOPLE may consider industrial lubricants to be a secondary consideration to machine specification. However relying on a thin film of liquid to separate moving parts, reduce friction and dissipate heat efficiently can mean achieving enhanced production efficiencies in machining costing many thousands of pounds, and at the same time reducing machinery downtime, David Wright, director general of the United Kingdom Lubricants Association (UKLA) explains.

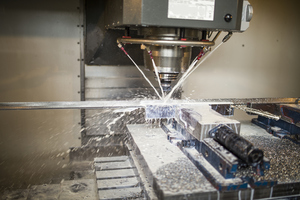

Put simply the types of lubricants we use in metalworking applications perform a critical function whether this is broaching, milling, grinding, cutting, rolling, or forming of surfaces. These types of activities rely on the ability of the fluid to perform at high temperatures in high speed environments, so the performance characteristics of the fluid is key.

There are generally two types of metalworking fluids; Neat oils and water-mix fluids. Neat Oils are oil or vegetable-based fluids used where a high surface finished is required. Their function is to reduce friction to enable the cutting action, reduce heat at the cutting edge, remove metal chips and debris away from the head, and improve the surface finish that is being cut. Neat Oils also help deliver production efficiencies and the right fluid can help improve the life of the machine by, for example, protecting against corrosion.

Water-mix fluids are widely used in general machining operations on account of their low cost and cooling capability. They perform the same functions as Neat oils, and are used in a diluted form, hence the term water-mix.

Both Neat oils and water-mix fluids are comprised of base oils and additives. The base oil can be oil or vegetable-based and comprises of the majority of the volume of the finished product, perhaps as much as 80%. However additives are used to enhance the properties of the fluid which otherwise would not be able to exhibit the same performance characteristics.

The three main types of water-mix fluids are:

Conventional 'milky' emulsions

High oil content of between 60-80% that can be relatively economic in price and may contain biocide for bacterial protection, as bacteria can sometimes grow in these types of fluids depending on environmental and operational conditions. The opaque appearance is due to the comparatively large size of the emulsion droplets that prevent the transmission of light.

Semi-synthetic translucent emulsions

Generally these products contain between 5-60% oil and are translucent in appearance due to the smaller droplet size. These products may have a relatively long sump life because of the presence of additives that limit bacterial growth.

Fully synthetic solutions

This type of solution is completely watermiscible giving a true solution which is clear in appearance. As the name suggests this product is completely free of oil and is often to be found in grinding operations. With the addition of performance additives, these products can be used for a wide spectrum of operations. A wide variety of factors influence the specific fluid selection. For tough materials (e.g. inconel, titanium, etc.), or for tough machining operations such as deep hole drilling, a fluid with some form of extreme pressure additive is necessary.

Selecting the right fluid

The following questions are key to selecting the right fluid for the operation: What type of material is being machined? What machining operation is involved? What is the quality (hardness) of the dilution water? What other specific requirements e.g. surface finish, freedom from staining, are there?

Metals to be machined

Steel

Low tensile steels can be readily machined, unlike the higher tensile steels which are more difficult to machine. The higher tensile steels, such as stainless, tool and alloy steels require the use of some form of extreme pressure additive. Staining is not a problem when machining steels.

Cast iron

Cast iron is easily machinable due to the presence of graphite, except for white cast iron which is strong and hard and difficult to machine. Fluids with a low oil content must be used. For normal cast irons to minimise ‘drag out’ of oil by the fine swarf particles. Staining is not a problem when machining cast iron.

Aluminium

Aluminium is a soft 'draggy' material, which can make it difficult to achieve a good surface finish. Lubricity additives, normally in the form of a fatty material, are necessary. Additives containing chlorine or sulphur must be avoided as these will result in staining. Staining can be reduced by the incorporation of a passivator.

Copper and copper alloys

These are generally soft, 'draggy' metals which are difficult to machine. Fluids should therefore contain some form of extreme pressure additive together with a passivator. Insoluble copper soaps can be formed during the process, which will turn the fluid green and could exacerbate the tendency to staining.

Titanium

Titanium can tend to work harden, and is usually cut at low speeds. Often used in aerospace work along with aluminium alloys and therefore an aluminium coolant is often used a rationalisation product. Chlorine and sulphur extreme pressure agents should generally be avoided due to the potential for stress crack corrosion.

Magnesium

Magnesium exhibits excellent machining properties, and a good surface finish can be readily obtained. Care must be taken as magnesium swarf can react exothermically (generating heat) with water. The use of sulphurised additives must be avoided otherwise staining can occur.

Nickel

Nickel and its alloys are prone to work-hardening so low cutting speeds are essential. Extreme pressure additives are necessary to ensure adequate machining performance. The use of sulphurised additives must be avoided otherwise staining can occur.

Overall operating costs

The metalworking fluid functions as one component of the production process. Its cost, although significant, is relatively low compared with the other costs of product support and maintenance. Even so, it can be false economy to focus on lower priced metalworking fluids, since the extended working life of a synthetic fluid for example can result in lower overall operating costs.

Fluid care

The two key factors involved in fluid maintenance are dilution and contamination. If the fluid concentration is too low then corrosion and bacterial contamination can occur, along with poor machining performance.

If the fluid concentration is too high, the potential for skin irritation, foaming, sticky deposits and paint removal can increase. In ideal conditions, bacteria can multiply every 20 minutes - which means that in 8 hours one single bacteria can produce a colony of 8,000,000. If in doubt ask your fluid supplier for advice.

Fluid disposal

Unless specific agreement has been granted by the local water authority, and this is strictly controlled, disposal to drain (either foul or rainwater) is not an option. Fluids should normally be stored pending collection with disposal arranged via an authorised waste contractor.

The fluids are normally disposed of by splitting where possible to separate the aqueous component, which is then further treated, whilst the oil component is normally incinerated. The quantity of waste fluid, together with the associated disposal costs, can be minimised by the use of a high quality long life fluid coupled with good fluid management

- Healthy trucks, healthy site

- The Sound of Silence: Communicating with machines

- Inspection, test & monitoring: A choice of career development pathways

- Compressor efficiency: Specification matters

- Raising issues of concern

- Mattei explains why compressor maintenance is essential

- Maintec 2013: Innovation galore

- Co-Locations for Maintec 2014

- Maintaining strategies for success

- Considerations for machine tool maintenance