|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Boilers and burners | >Responding to today's needs |

ARTICLE

Responding to today's needs

25 January 2013

New boiler designs shift the emphasis from low purchase prices to low running costs and emissions.Peter Baldwin,MD of Byworth boilers looks at recent developments Twenty years ago industrial boiler design was driven m

New boiler designs shift the emphasis from low purchase

prices to low running costs and emissions.Peter Baldwin,MD

of Byworth boilers looks at recent developments

Twenty years ago industrial boiler design was driven mainly by the demands of equipment buyers and specifiers for boilers which produced maximum output at minimum purchase price.Many boilers were designed to be small, with the least steel, tube and insulation possible without greatly affecting reliability and output. This often resulted in mediocre efficiency, with higher fuel and power consumption and NOx emissions.

How things have changed. Now, with the exception of those organisations that have a source of cheap fuel, there cannot be any boiler project which doesn't prioritise running costs and reliability over purchase price. Boiler shells and furnaces should be generously sized, not minimised to save on steel costs. A steam space which is too small causes priming and 'carry over' of water in the steam system resulting in wet steam, dissolved solids in the process, scaling and water hammer.

To reduce NOx emissions, the furnace length to diameter ratio should ideally be 3.5 to 1. Likewise, a lower volumetric heat release from the furnace forms less NOx as the flame temperature is cooler.

X-ID Tubes The quest to improve efficiency has led to innovations such as X-ID tubes. These have internal helical ribs and increase the heat transfer from the tubes to water space by over 80%. This is achieved due to the larger surface area and due to a boundary layer attachment/re-attachment phenomenon.

Hot gases leave the boiler at lower temperatures than from plain tubes, with much less heat wasted in flue gases.

Installations of boilers in the UK with X-ID tubes providing ongoing fuel savings without compromising reliability. X-ID tubing is suitable for gas or oil fired boilers, including those on heavy fuel oil.Maintenance is no higher than with plain tube.

Pre-heating combustion air The latest development in steam boiler technology has seen the introduction of the Pre-heat boiler which has an air-to-air heat exchanger to pre-heat the combustion air.

Fluegas economisers Fluegas economisers can improve boiler efficiency by up to 5%. The heat in flue gases, which would otherwise be lost up the stack, is used in an air to water heat exchanger to pre-heat the feed water to the boiler. Even after the flue gases have passed through the economiser there is still usable heat. An air-to-air heat exchanger above the economiser draws clean air past banks of tubes in which the flue gases pass en route to the stack. The combustion air then travels through specially designed ducting that has a bypass section for use should pre-heating not be required. Air pre-heaters can be used without an economiser, providing costeffective fuel saving on all fuels.

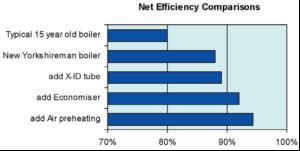

Energy cost comparison In an energy cost comparison based on 10,000kg/h boilers fired with natural gas, price 2.8p/kWh running 24/7 for 50 weeks a year, boiler A is a typical boiler with an average efficiency of 80%, boiler B is a Byworth Yorkshireman2 with X-ID tube, economiser and Air pre-heating. Saving per year is around £135,000; payback for a whole boiler replacement project including installation would be around 12 months.

Waste heat boilers Many operations create heat as a waste product, for example anaerobic digestion, incineration and power generation. There are many projects to investigate the use of this waste heat to produce hot water for heating or steam for process applications.

Waste heat boilers operate on the same principles as a conventional boiler but instead of coming from a burner the energy to raise the hot water or steam comes purely from waste heat. However, if the supply of waste heat is not consistent or sufficient, a combination boiler can be used which has supplementary firing. Flue gas economisers can be included to increase efficiency and XID tubes enable shorter shell lengths. Projects are individual so waste heat boilers need to be custom-designed and built to gain peak performance and optimum pressure drops.

Alternative fuels Boiler manufacturers continue to explore the benefits of alternative fuels. As well as the obvious benefits to the environment, renewable fuels such as wood chips or wood pellets may deliver considerable savings.

Add-on technology To support the increased efficiency of the boilers themselves there have been significant technological advances in burners and boiler controls. Burners with electronic air and fuel control give better efficiency right across the turn down range and reduce NOx emissions.

VSDs on burners and feed water pumps will reduce electrical consumption while automatic blowdown and TDS control systems boost efficiency.

Twenty years ago industrial boiler design was driven mainly by the demands of equipment buyers and specifiers for boilers which produced maximum output at minimum purchase price.Many boilers were designed to be small, with the least steel, tube and insulation possible without greatly affecting reliability and output. This often resulted in mediocre efficiency, with higher fuel and power consumption and NOx emissions.

How things have changed. Now, with the exception of those organisations that have a source of cheap fuel, there cannot be any boiler project which doesn't prioritise running costs and reliability over purchase price. Boiler shells and furnaces should be generously sized, not minimised to save on steel costs. A steam space which is too small causes priming and 'carry over' of water in the steam system resulting in wet steam, dissolved solids in the process, scaling and water hammer.

To reduce NOx emissions, the furnace length to diameter ratio should ideally be 3.5 to 1. Likewise, a lower volumetric heat release from the furnace forms less NOx as the flame temperature is cooler.

X-ID Tubes The quest to improve efficiency has led to innovations such as X-ID tubes. These have internal helical ribs and increase the heat transfer from the tubes to water space by over 80%. This is achieved due to the larger surface area and due to a boundary layer attachment/re-attachment phenomenon.

Hot gases leave the boiler at lower temperatures than from plain tubes, with much less heat wasted in flue gases.

Installations of boilers in the UK with X-ID tubes providing ongoing fuel savings without compromising reliability. X-ID tubing is suitable for gas or oil fired boilers, including those on heavy fuel oil.Maintenance is no higher than with plain tube.

Pre-heating combustion air The latest development in steam boiler technology has seen the introduction of the Pre-heat boiler which has an air-to-air heat exchanger to pre-heat the combustion air.

Fluegas economisers Fluegas economisers can improve boiler efficiency by up to 5%. The heat in flue gases, which would otherwise be lost up the stack, is used in an air to water heat exchanger to pre-heat the feed water to the boiler. Even after the flue gases have passed through the economiser there is still usable heat. An air-to-air heat exchanger above the economiser draws clean air past banks of tubes in which the flue gases pass en route to the stack. The combustion air then travels through specially designed ducting that has a bypass section for use should pre-heating not be required. Air pre-heaters can be used without an economiser, providing costeffective fuel saving on all fuels.

Energy cost comparison In an energy cost comparison based on 10,000kg/h boilers fired with natural gas, price 2.8p/kWh running 24/7 for 50 weeks a year, boiler A is a typical boiler with an average efficiency of 80%, boiler B is a Byworth Yorkshireman2 with X-ID tube, economiser and Air pre-heating. Saving per year is around £135,000; payback for a whole boiler replacement project including installation would be around 12 months.

Waste heat boilers Many operations create heat as a waste product, for example anaerobic digestion, incineration and power generation. There are many projects to investigate the use of this waste heat to produce hot water for heating or steam for process applications.

Waste heat boilers operate on the same principles as a conventional boiler but instead of coming from a burner the energy to raise the hot water or steam comes purely from waste heat. However, if the supply of waste heat is not consistent or sufficient, a combination boiler can be used which has supplementary firing. Flue gas economisers can be included to increase efficiency and XID tubes enable shorter shell lengths. Projects are individual so waste heat boilers need to be custom-designed and built to gain peak performance and optimum pressure drops.

Alternative fuels Boiler manufacturers continue to explore the benefits of alternative fuels. As well as the obvious benefits to the environment, renewable fuels such as wood chips or wood pellets may deliver considerable savings.

Add-on technology To support the increased efficiency of the boilers themselves there have been significant technological advances in burners and boiler controls. Burners with electronic air and fuel control give better efficiency right across the turn down range and reduce NOx emissions.

VSDs on burners and feed water pumps will reduce electrical consumption while automatic blowdown and TDS control systems boost efficiency.

MORE FROM THIS COMPANY

- Full steam ahead for boiler hire fleet

- Ready to roll

- Hired boilers in hospital role

- Rising to the challenge

- A fresh view on boilerhouse control

- Biomass enquiries rise

- Raising the bar for steam boiler efficiency

- Boiler investment: Selection matters

- Steam expertise

- Biomass boilers: 'Whole solution' approach

OTHER ARTICLES IN THIS SECTION