|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Inspection, traceability & code reading |

ARTICLE

Inspection, traceability & code reading

25 January 2013

With tracking and traceability a key element in many manufacturing industries, Stemmer Imaging will be showing an extensive range of camera technologies and systems for code reading, verification and traceability, as w

With tracking and

traceability a key element

in many manufacturing

industries, Stemmer Imaging will be

showing an extensive range of camera

technologies and systems for code

reading, verification and traceability,

as well as traditional inspection

applications. As a large, independent

supplier of vision technology and

services to OEMs, system Integrators

and reseller markets, the company

will be showing smart cameras

including 3D smart cameras,

multipoint intelligent inspection

systems and linescan cameras

demonstrating code reading

capabilities at over 1200 parts/minute.

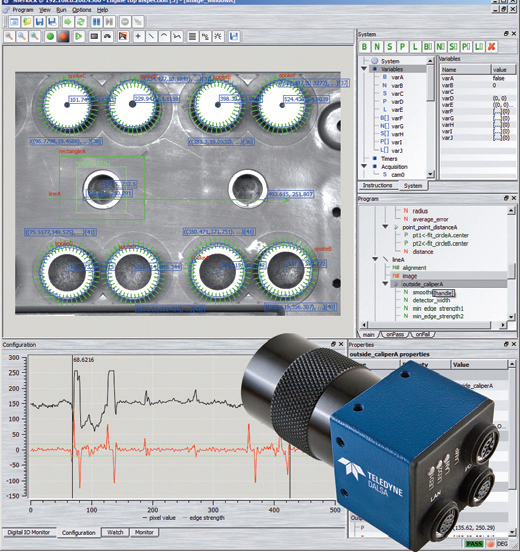

Among the products on display, BOA smart cameras from Teledyne DALSA are robust, compact, fully integrated intelligent vision systems designed for harsh environment factory floor deployment. The BOA IDR version combines 1D barcode, 2D matrix and character reading and verification with pattern recognition capabilities in a single unit for check - ing barcodes, 'best before' dates, lot numbers and even logos. Stand 5050

Among the products on display, BOA smart cameras from Teledyne DALSA are robust, compact, fully integrated intelligent vision systems designed for harsh environment factory floor deployment. The BOA IDR version combines 1D barcode, 2D matrix and character reading and verification with pattern recognition capabilities in a single unit for check - ing barcodes, 'best before' dates, lot numbers and even logos. Stand 5050

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION