|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Measurement: Do your level best |

ARTICLE

Measurement: Do your level best

25 January 2013

Correct specification of level sensors can improve the efficiency of industrial and process operations, as Charlie Sorbo, level product manager for Gems Sensors and Controls, explains Level measurement is a fundamenta

Correct specification of level sensors can improve the

efficiency of industrial and process operations, as Charlie

Sorbo, level product manager for Gems Sensors and

Controls, explains

Level measurement is a fundamental requirement of many industrial and process applications and the demands of plant managers have driven the designers and engineers behind level sensors to provide components that offer increased reliability, lower maintenance costs and far greater levels of precision.

When specifying a level measurement solution, there are several factors to consider.

Cost is rarely the primary one, since the original saving made by selecting the lowcost option is often outweighed by the expense of on-going maintenance. More important factors are the nature of the process material that is to be measured and its material characteristics. Temperature and pressure levels will need to be considered, as will the substance of the tank that holds the material. Specification also depends heavily upon whether the process material is a liquid, a slurry or a solid.

Compare, for example, the methods of RF capacitance and conductivity in level measurement. RF capacitance works on the principle that the electrical capacitance between two separated conductors changes when the space between them is interrupted by a quantity of non-conducting material.

For example, a conductive, sensing electrode can be lowered into a metal tank to act as one conductor, while the wall of the tank acts as the other. As the level of process material rises, covering a greater area of the suspended electrode, a change in capacitance is measured between the two conductors and this is transmitted to an RF level transmitter on the exterior of the tank, providing a direct measurement of tank level. However, in some applications, a steady build-up of process material residue begins to coat the level-sensing probe, causing errors of measurement. Conductive level measurement can avoid this problem. Here, liquid level measurement is achieved via the electrical conductance of the process material, typically a liquid with a low-voltage source, and offers a relatively low-cost, simple method of detecting and controlling level. In a tank of liquid, conductive sensors are positioned at high and low points in the tank to detect maximum and minimum levels. When the level of process material rises to reach the upper probe, a switch closes to activate a discharge pump; when the process material makes contact with the lower probe, the switch opens to stop the pump. Conductive level measurement is not always the best option, but the example illustrates the importance of carefully considering the properties of the process material before specifying the sensors.

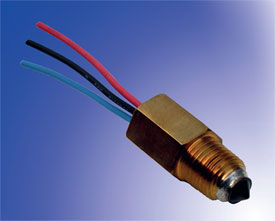

Electro-optic sensors offer a further method of measuring level. An electro-optic sensor contains both an infrared LED and a light receiver. Infrared light from the LED is directed into a prism at the tip of the sensor and, when no liquid is present, the light is reflected within the prism to the receiver; however, when liquid rises in the vessel to immerse the prism, the light from the infrared LED is refracted out into the liquid.

At this point, there is no longer any light reaching the receiver, which actuates electronic switching to operate an external alarm or control circuit. There are now electro-optic components on the market with the potential to operate within extreme temperatures ranging between -40 and +125°C, offering ingress protection ratings of IP66 and upwards, which can be used even within extreme environmental conditions.

The robust construction of today's electrooptic sensors, such as the Gems Sensors & Controls ELS 950M, coupled with the high levels of performance and reliability they offer, has enabled accurate level measurement across a range of industries, providing powerful, cost-effective solutions for plant managers in many applications. Here, a modern, solidstate, liquid level sensor with no moving parts can perform the same task as a capacitance sensor without the reduced performance that can occur when a capacitance sensor becomes coated by the process material and begins to give false readings.

All these innovations in level measurement offer huge potential but to get the best from any component you need to ensure the right specification for your operations. This may even involve supplying a sample of the process material for evaluation, along with a diagram of the vessel, when working with your sensor supplier. The effort will be worthwhile and ensure maximum performance with minimal maintenance requirements for your industrial and process operations.

Level measurement is a fundamental requirement of many industrial and process applications and the demands of plant managers have driven the designers and engineers behind level sensors to provide components that offer increased reliability, lower maintenance costs and far greater levels of precision.

When specifying a level measurement solution, there are several factors to consider.

Cost is rarely the primary one, since the original saving made by selecting the lowcost option is often outweighed by the expense of on-going maintenance. More important factors are the nature of the process material that is to be measured and its material characteristics. Temperature and pressure levels will need to be considered, as will the substance of the tank that holds the material. Specification also depends heavily upon whether the process material is a liquid, a slurry or a solid.

Compare, for example, the methods of RF capacitance and conductivity in level measurement. RF capacitance works on the principle that the electrical capacitance between two separated conductors changes when the space between them is interrupted by a quantity of non-conducting material.

For example, a conductive, sensing electrode can be lowered into a metal tank to act as one conductor, while the wall of the tank acts as the other. As the level of process material rises, covering a greater area of the suspended electrode, a change in capacitance is measured between the two conductors and this is transmitted to an RF level transmitter on the exterior of the tank, providing a direct measurement of tank level. However, in some applications, a steady build-up of process material residue begins to coat the level-sensing probe, causing errors of measurement. Conductive level measurement can avoid this problem. Here, liquid level measurement is achieved via the electrical conductance of the process material, typically a liquid with a low-voltage source, and offers a relatively low-cost, simple method of detecting and controlling level. In a tank of liquid, conductive sensors are positioned at high and low points in the tank to detect maximum and minimum levels. When the level of process material rises to reach the upper probe, a switch closes to activate a discharge pump; when the process material makes contact with the lower probe, the switch opens to stop the pump. Conductive level measurement is not always the best option, but the example illustrates the importance of carefully considering the properties of the process material before specifying the sensors.

Electro-optic sensors offer a further method of measuring level. An electro-optic sensor contains both an infrared LED and a light receiver. Infrared light from the LED is directed into a prism at the tip of the sensor and, when no liquid is present, the light is reflected within the prism to the receiver; however, when liquid rises in the vessel to immerse the prism, the light from the infrared LED is refracted out into the liquid.

At this point, there is no longer any light reaching the receiver, which actuates electronic switching to operate an external alarm or control circuit. There are now electro-optic components on the market with the potential to operate within extreme temperatures ranging between -40 and +125°C, offering ingress protection ratings of IP66 and upwards, which can be used even within extreme environmental conditions.

The robust construction of today's electrooptic sensors, such as the Gems Sensors & Controls ELS 950M, coupled with the high levels of performance and reliability they offer, has enabled accurate level measurement across a range of industries, providing powerful, cost-effective solutions for plant managers in many applications. Here, a modern, solidstate, liquid level sensor with no moving parts can perform the same task as a capacitance sensor without the reduced performance that can occur when a capacitance sensor becomes coated by the process material and begins to give false readings.

All these innovations in level measurement offer huge potential but to get the best from any component you need to ensure the right specification for your operations. This may even involve supplying a sample of the process material for evaluation, along with a diagram of the vessel, when working with your sensor supplier. The effort will be worthwhile and ensure maximum performance with minimal maintenance requirements for your industrial and process operations.

MORE FROM THIS COMPANY

- Energy efficient solenoid valves

- Level switches

- Gems Sensors and Controls Launches New Website

- New digital output sensor option for Gems RotorFlow series

- Level switches

- Low range pressure transducer launched

- Sensor range saves time and cost in hazardous applications

- Gems introduces innovative sensor to detect water in fuel

- GEMS SENSORS & CONTROLS INTRODUCES A ROBUST NO-MOVING-PARTS THERMAL DISPERSION FLOW SWITCH AT OEM PRICING

- White paper for designers of medical devices

OTHER ARTICLES IN THIS SECTION