|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Kistler Instruments at PDM 2013 |

Kistler Instruments at PDM 2013

28 May 2013

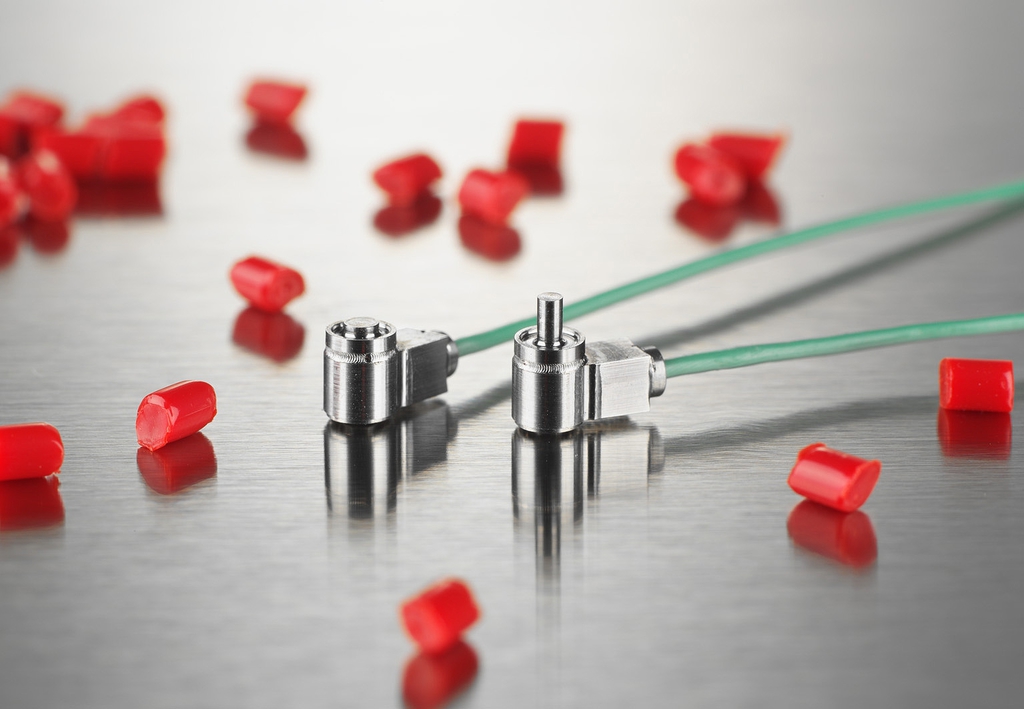

At PDM (18th-19th June, Telford International Centre) Kistler Instruments will be showing its injection moulding instrumentation for 'Zero Reject' quality control.

The latest version of the Kistler CoMo Injection cavity pressure monitoring system provides mould recognition and automatic loading of mould data, making mould connection and setting easier and faster during mould changes.

New connectors, with mould ID Chips, simplify loading of mould and product data sets and indicate connection errors on the CoMo Injection touch screen display or PC. Connection errors are detected quickly and can be corrected before problems occur.

To support CoMo Injection, the Kistler Stasa QC software for injection moulding, with the help of a statistical Design of Experiments, systematically determines the effect of relevant machine parameters on part quality and optimises the operating point, taking into account all optimisation targets.

- Triple launch at sensors show

- Measures torque and speed Good report for grinder Protean Electric is

- Zero defect moulding? Kistler white paper explains more

- X-Y monitoring system

- New modules join the range

- Electro-mechanical joining modules

- Small addition

- Perfect rejection of faulty parts

- Built-in speed sensor

- 4 billion miles: One tank of fuel