|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Pressure sensor validates |

Pressure sensor validates

17 November 2014

The National Physical Laboratory (NPL) is working on a dynamic pressure sensor calibration method, based on shock tube techniques, which NPL hopes will be adopted as an ISO standard.

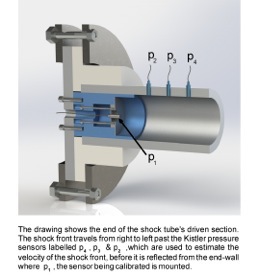

The methodology uses a shock tube, in which a bursting disc separates two sections, and an increasing pressure in one section initiates failure of the disc, creating a pressure shock wave in the other section. This shock wave is used to calibrate the sensor under test mounted in the section’s end wall.

The shock tube performance has been validated using a Kistler Instruments Type 603B miniature piezoelectric pressure sensor with acceleration compensation, designed specifically for measuring pressure fluctuations of high frequency and short rise time, and the Type 5015 single channel laboratory charge amplifier with a wide measuring range.