|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Motors and drives | >Latest servo drives |

| Home> | Energy Management | >Motors and drives | >Latest servo drives |

Latest servo drives

25 July 2013

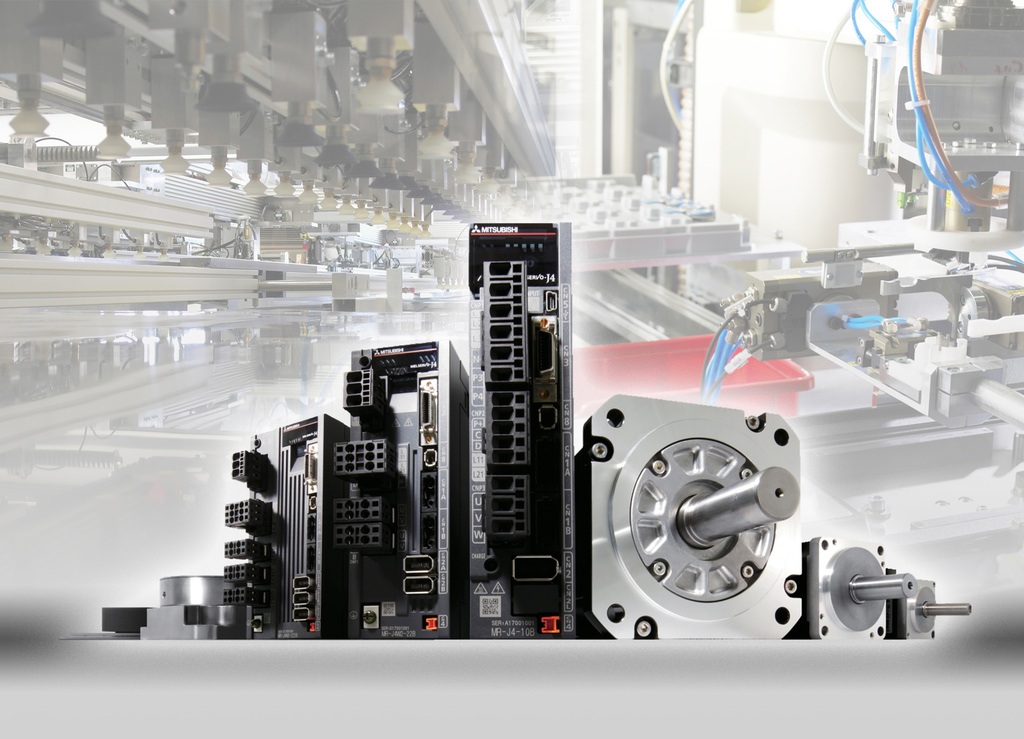

Mitsubishi Electric believes that its MR-J4 series of servo amplifiers represents a significant advance in servo system technology that will provide benefits both to machine builders and end users.

The MELSERVO MR-J4 series of servo amplifiers, complete with associated positioning units, easy to use motion modules and high end integrated motion control systems are designed to enable machine builders and users to improve productivity and reduce energy costs.

The series features single, dual and triple axis amplifiers. The servos can operate with rotary, linear and direct drive motors, simplifying the system building process. In addition to saving space in the panel, engineering and commissioning time is reduced due to the one-touch auto tune function, which matches the machine mechanics to the servo system in a single operation. This operates in real time and is dynamic, so if machine conditions change, the MR-J4 system tuning automatically adjusts.

Covering the range from 0.1 to 55kW, the servo amplifiers are available in two versions. The MR-J4A provides analogue and pulse train connections and is designed for conventional control systems and for speed, torque and closed-loop position control. The MR-J4B comes with connectivity to Mitsubishi Electric’s SSCNETIII/H high performance servo network, meeting the needs of integrated automation systems where complex multi-axis motion control is required.

The amplifiers include a 'life diagnosis function' which monitors the condition of the amplifier at a component level and notifies the user of any degradation in its operation. This feature can also recognise changes in machine dynamics such as increased vibration and increased motor torque.

Servo motors are fitted with 22-bit absolute encoders as standard, corresponding to more than four million pulses per revolution. Mitsubishi Electric says the result is excellent true-running characteristics and maximum positioning accuracy.

Features such as STO (Safe Torque Off) and SS1 (Safe Stop 1) are built in as standard; SS2, SOS, SLS, SBC and SSM safety options are available.

- Energy efficient hand dryer is fast operator

- Firmware option reduces programming

- G5-5 harmonic recommendations

- Servos help pack print

- Creating a stir in white sauce production

- Integrated display

- Industrial food cutting becomes a piece of cake

- Cyber security: Journey not destination

- HMIs feature intuitive operating concept

- Industrial automation training