|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Grinding and abrasives | >Made-to-Measure diamond tools |

| Home> | Handbooks | >Manufacturing Matters Ireland | >Made-to-Measure diamond tools |

Made-to-Measure diamond tools

04 November 2013

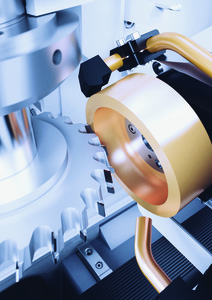

Vollmer reports an excellent response to its new eroding machine – the QXD 250 – at the recent EMO exhibition.

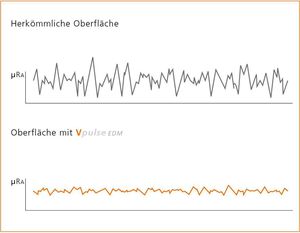

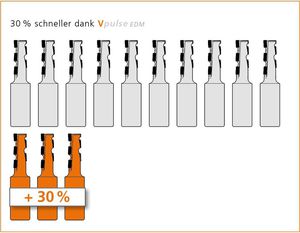

Due to its new Vpulse EDM generator technology, the QXD 250 is said to be able to produce PCD tipped (polycrystalline diamond) tools up to 30% faster than previously. Vollmer says that with targeted eroding impulses, it can increase the surface fineness by a factor of two or more. This gives the QXD 250 more flexibility in terms of tool production.

Dr. Stefan Brand, MD, says: "The QXD 250 eroding machine makes it possible for our customers to completely process PCD tools. Diamond tools such as face milling, groove milling or slot milling cutters can be exactly sharpened and tailor-manufactured for an ever increasing number of industrial sectors.”

- Software opens new opportunities for saw blades

- Circular saw cuts cycle times

- Vollmer unveils digital roadmap for the future

- Laser Focus With New VOLLMER Arrival

- Selecting a production machine for medical industry tools

- Vollmer 'hitting the ground running' at AMB 2022

- Vollmer helps Systco achieve lights-out production

- Grinding machine carves through blades

- Grinding technology for carbide tools