|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Grinding technology for carbide tools |

Grinding technology for carbide tools

02 December 2021

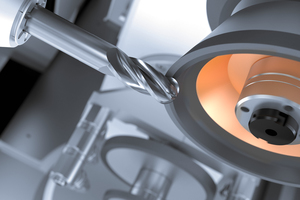

GERMAN MANUFACTURER Vollmer has exhibited its VGrind 360S grinding machine for the first time. The machine is for the complete machining of rotationally symmetric solid carbide tools.

At the recent EMO show, Vollmer gave the exhibition premiere of its new VGrind 360S grinding machine for the complete machining of carbide tools. Acknowledged as the new standard for the complete machining of rotationally symmetric solid carbide tools for aerospace, medical, automotive and general subcontract manufacturing sectors.

The 5-axis CNC grinding machine can be used productively to machine carbide tools with a diameter up to 25.4mm and, depending on the machine kinematics and the specification of the grinding wheel packages, it can even be used for tools up to 150mm diameter. The VGrind 360S incorporates wear-free linear induction motors on the X, Y and Z-axes which the company claims will lower maintenance costs for the machine while demonstrating higher surface quality for the tool and improved precision.

Vollmer's vertical double-spindle concept now features an oriented spindle-stop for the first time. Also known as spindle indexing, this feature stops the spindle at a specific position, resulting in a reduction of axial run-out errors and concentricity issues whilst offsetting wear in the HSK holding system. Another new feature is a heat plate exchanger to cool motors and spindles, which in turn leads to increased thermal stability. =

Vollmer has created an ergonomic platform through which users can operate the control panel comfortably ,while having full visibility of the work envelope. Operation via the keyboard or touchscreen allows for precise machining of the too,l and the multi-function handwheel ensures even more flexibility as it can be freely positioned on the enclosure. This design allows for the setting of a required axis without using the control panel.

The VGrind 360S can be operated unmanned around the clock thanks to automation features such as a pallet magazine, free-arm robot or chain magazine. The options for automation include the HP 160 pallet magazine for up to 900 tools with a double gripper to guarantee fast changeovers, the HPR 250 free-arm robot for the automatic machining of tools with various shaft diameters and the HC 4 chain magazine that has space for 39 HSK-63A tools or up to 158 shank-type tools. This automation also extends to the 8-tool grinding wheel changer that ensures you always supply the right grinding wheel for the job at hand with no manual intervention. As an option, coolant nozzles can be automatically exchanged with the wheel sets on both spindles.

Optional features include flexible loading automation options for carbide tools, grinding spindles with direct or belt drive, automatic gripper compensation as an in-process solution, wheel compensation probes, automated changing of intermediate sleeves with bayonet, and an automatic stacking unit that enables the abrasive grinding wheel to be opened during the grinding process. Other available features include the simultaneous grinding wheel package, and tool change in combination with the HP 160 pallet magazine, or the HC 4 to reduce non-productive times during loading, and a stable, fully adjustable steady rest with automatic stroke to prevent deflection and ensure optimal grinding results.

- Grinding machine carves through blades

- Software opens new opportunities for saw blades

- Vollmer helps Systco achieve lights-out production

- Vollmer unveils digital roadmap for the future

- Made-to-Measure diamond tools

- Circular saw cuts cycle times

- Vollmer 'hitting the ground running' at AMB 2022

- Laser Focus With New VOLLMER Arrival

- Selecting a production machine for medical industry tools