|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Grinding and abrasives | >Grinding wheels |

Grinding wheels

30 July 2013

3M has introduced a range of bonded abrasive grinding wheels into the European market which, it believes, will offer a new approach to the grinding process.

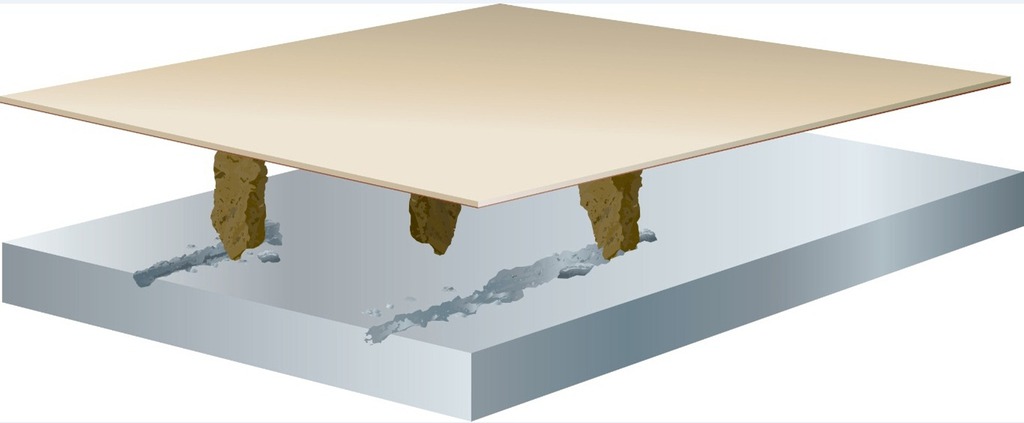

Using the advanced abrasive grain technology, precision shaped grain, introduced with the Cubitron II Abrasive Belts and Discs from 3M, the new grinding wheels are said to cut faster, last longer and require less pressure than conventional grinding wheels, resulting in increased productivity and reduced operator fatigue.

Suitable for heavy weld removal as well as numerous other grinding applications, Cubitron II Bonded Abrasive Grinding Wheels are capable of delivering high cut rates on an extensive range of metals and can be used across a wide range of industries.

- Smart electronic earplugs block only loud noises

- More than just a product

- 3M scores with Old Trafford crowd

- New 3M safety helmet range delivers performance and comfort

- Latest bump cap

- Breathing safely

- Practicality plus style

- On show at A+A 2017

- Working at height: separating fact from fiction

- More choosing to stick together