|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Keeps the metering lines flowing |

Keeps the metering lines flowing

20 November 2013

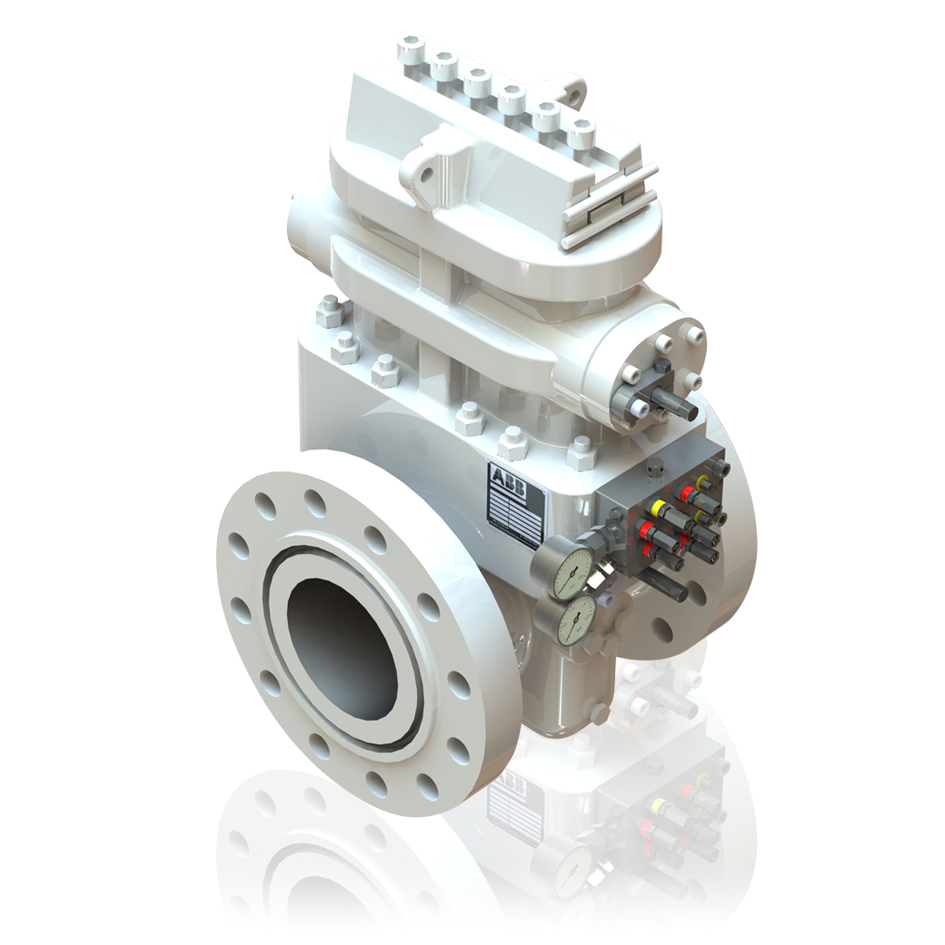

ABB says disruption in fiscal metering applications caused by the removal and inspection of orifice plate flowmeters can be eliminated using its new meter2di FPF220.

The device is a dual-chamber orifice fitting that enables orifice plates to be inspected or replaced without removing the fitting itself from the pipeline.

Many orifice meters used in the oil and gas industry typically feature a single chamber design. Single chamber fittings have an orifice plate that can be replaced without removing the fitting from the pipeline. However, before the plate can be withdrawn, the flow must first be stopped and the pipeline vented, causing potential disruption.

ABB's meter2di overcomes this by enabling safe removal of the orifice plate while the line remains pressurised and the product is flowing. The plate is withdrawn into a dual chamber, which is then isolated from the pipeline. Although the second chamber must be vented, the pipeline itself need not be vented.

Added protection against the risk of leakage from pipeline to the second chamber during plate removal is provided by the meter2di's dual isolation feature. This uses two independent chamber seals to ensure maximum safety during live orifice plate changes or routine inspections.

Valve isolation is provided by ‘Category II Proved Isolation' using a double block and bleed arrangement. All chamber equalisation and venting is controlled by a single manifold that can be supplied as 'firesafe' if required.

- MCERTS for pH measurement

- Analytical panel hire service

- ABB signs modernisation agreement with Billerud to future-proof operations

- Online selector tool

- New motor cuts energy and maintenance costs

- Self-powered temperature transmitter

- Introducing the next generation of pressure measurement devices from ABB

- ABB launches new Low-Force System for ultra-thin metal strip applications

- ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

- Analytical panel hire service